Thepowerful permanent magnetic chuck, as an efficient, energy-saving and easy-to-operate tool for holding workpieces, is widely used in various fields such as metal processing, assembly, and welding. By using permanent magnets to provide persistent suction force, the powerful permanent magnet suction cup significantly enhances production efficiency, saves time and costs. This article will provide a detailed introduction to the technical principles, product advantages, usage restrictions and maintenance methods of the powerful permanent magnet suction cup, helping users better understand and use this equipment.

I. Technical Principle of the Powerful Permanent Magnetic Chuck

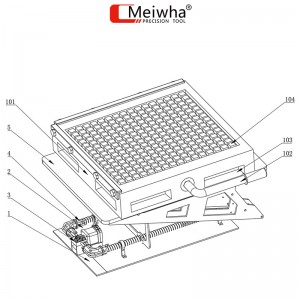

Chuck Internal structure diagram

1.Three-dimensional magnetic circuit superposition design

- Double-layer magnetic pole structure:

A double-layer magnetic circuit is formed by using an inverted T-shaped core and a side-lying plate. Neodymium-iron-boron magnetic steel (with the N pole oriented) and the bottom aluminum-nickel-cobalt magnetic steel form three independent closed circuits. The magnetic force lines circulate from the core → the workpiece → the outer plate → the bottom plate → the core, thereby increasing the magnetic field density by more than 16%.

- Magnetic centripetal focusing:

The inverted T-shaped core converges the magnetic lines at the edges towards the center, addressing the issue of insufficient adhesion for narrow workpieces (such as guides and blades), and the minimum compatible workpiece size reaches 50×50×2mm.

2.Halbach Array Enhancement

- Cross-shaped permanent magnet array:

The high-end model adopts a two-dimensional "cross" type Halbach array. Through the specific arrangement of permanent magnets (with N-S poles rotating alternately), it autonomously guides the direction of the magnetic field, increasing the magnetic flux density on one side of the working surface by 50% and reducing the leakage magnetic flux by 30%.

- Optimization of Magnetic Energy Utilization Rate:

Under the same volume, the Halbach array increases the magnetic force density from 120N/cm² in the traditional design to 180N/cm², while reducing the material usage by 20%.

| Type of magnetic material | key role | performance parameter | application scenarios |

| NdFeB(neodymium iron boron) | High coercivity (≥ 955 kA/m) anti-demagnetization capability | Remanent magnetism Br = 1.26 - 1.29 T | The main magnetic pole ensures strong adhesion. |

| Aluminum-nickel-cobalt | High residual magnetism (Br = 1.3T) enhances the magnetic field strength | Working temperature ≤ 460℃ | Auxiliary magnetic pole, enhances thermal stability |

| LNG permanent magnet | Variable polarity, responsive to electrical control signals | Retentive force: 56 kA/m | Magnetic circuit switching execution layer |

Synergistic effect: NdFeB provides anti-demagnetization capability, AlNiCo enhances the magnetic field penetration power, LNG enables polarity reversal. The three elements eliminate the magnetic potential differences through the buffer magnetic yoke, ensuring that the residual magnetism approaches zero during demagnetization.

II. Product Advantages of the High-Intensity Permanent Magnetic Chuck

Meiwha CNC Chuck

1.No need for an external power source

The powerful permanent magnetic Chuck provides fixation force through permanent magnets and does not require power supply. For some working environments that are far from power sources or where it is inconvenient to use electricity, the permanent magnetic chuck offers a very convenient solution.

2.Quick Installation and Disassembly

Compared with traditional mechanical fixtures or electromagnetic suction cups, the powerful permanent magnetic chuck have a faster installation and disassembly speed. With just a simple operation, the workpiece can be fixed or released, thereby enhancing the production line efficiency. They are particularly suitable for processing environments where the workpieces need to be changed frequently.

3.Stable suction ensures processing accuracy

The powerful permanent magnetic chuck provides uniform and stable adhesion force, effectively preventing the workpiece from moving or vibrating during the processing, thereby improving the processing accuracy and efficiency. It is particularly suitable for precision processing.

4.Save space costs

Due to the absence of power supply and complex control systems, powerful permanent magnetic chucks are usually designed to be more compact, making them suitable for working environments with limited space. Moreover, their lower maintenance costs and longer service life can effectively reduce the overall production costs.

5.Highly adaptable, suitable for various workpieces

The powerful permanent magnetic chuck can not only handle traditional metal workpieces, but also adapt to various shapes and sizes of workpieces. It can fix irregular and differently thick metal materials, meeting different processing requirements. (Partially, customizable magnet pole settings are planned to be supported)

III. Prohibited Applications of High-Intensity Permanent Magnetic Chuck

Although powerful permanent magnetic chuck have extensive applications in industrial production, users still need to be aware of the following prohibitions when using them, in order to prevent equipment damage or poor performance.

1.Avoid prolonged exposure to high temperatures.

High temperatures will cause the magnetic properties of permanent magnets to gradually weaken. Especially for high-performance rare earth magnets, prolonged exposure to an environment beyond their operating temperature range may lead to a decrease in suction force. Therefore, strong permanent magnetic chuck should avoid being used in working environments with excessively high temperatures.

2.Avoid contact with strong magnetic sources

The strong permanent magnetic chuck already has a strong magnetic force on its own. If it comes into contact with a stronger magnetic source, it may cause magnetic strength to decrease or even damage the suction cup. It is necessary to ensure that the strong permanent magnetic chuck is kept away from electromagnetic devices, high-frequency equipment, etc.

3.Avoid direct contact with corrosive substances

Corrosive chemical substances such as strong acids and strong bases can affect the surface of the permanent magnetic chuck, causing its magnetic property to decrease or be damaged. During operation, it is necessary to avoid the suction cup coming into prolonged contact with these substances, especially those without protective measures.

4.Avoid Overload Application

Although the powerful permanent magnetic chuck provides a large suction force, it also has its carrying limit. Overuse may lead to magnetic attenuation and even damage to the chuck structure, posing safety risks. Therefore, when using it, the appropriate weight of the workpiece should be selected based on the specifications of the chuck.

IV. Maintenance Methods for Strong Permanent Magnetic Chuck

Proper maintenance can not only extend the service life of the powerful permanent magnetic chuck, but also maintain its adhesion effect. Here are some common maintenance methods:

1.Regular cleaning

The surface of the chuck should be cleaned regularly to prevent the accumulation of metal shavings, oil stains or other debris. This is especially important during metal processing. You can clean the surface using compressed air or a soft cloth. It is not recommended to use hard objects to scrape it, as this may damage the magnetism.

2.Regularly check the magnetism

Although permanent magnetic chucks do not rely on an external power source, their magnetic force will still gradually weaken as the usage period increases. It is necessary to regularly check the suction force of the suction cups to ensure that they remain at a normal level. If the suction force is significantly reduced, consideration should be given to replacing the magnets or conducting maintenance.

3.Avoid violent collisions

The magnets in the powerful permanent magnetic chuck are fragile. Severe impacts may cause the magnets to break or the magnetic force to fail. During operation, one should be careful to avoid unnecessary collisions.

The powerful permanent magnetic chuck, with its advantages such as no need for power supply, quick installation and disassembly, and stable suction force, has become an indispensable tool in modern industrial production. With proper use and maintenance, it can significantly enhance production efficiency and processing accuracy. Understanding its technical principles, advantages, as well as the correct usage and maintenance methods is the key to ensuring its long-term efficient operation.

reference material:

Magnetic Clamping Technology - Guide on industrial magnetic clamps and their applications.

Industrial Magnetism - Basics of permanent magnets used in industrial tools.

Note: The specific product parameters are subject to the latest information provided by the manufacturer. Please visit our product center to learn more about the models or to request the selection report!

Post time: Aug-14-2025