Inserts

-

MGMN Meiwha CNC Turning Inserts Series

Work Material: 304、316、201steel、45#steel、40CrMo、A3steel、Q235steel,etc.

Machining Feature: The width of the insert is 2-6mm, which can meet various processing requirements such as cutting, slotting, and turning. The cutting process is smooth and the chip removal is efficient.

-

SNMG Meiwha CNC Turning Inserts Series

Groove Profile: Semi – fine processing

Work Material: 201、304、316、Common stainless steel

Machining Feature: Not prone to breaking, wear-resistant, long service life.

-

WNMG Meiwha CNC Turning Inserts Series

Groove Profile: Fine processing

Work Material: 201、304Common stainless steel、 Heat – resistant alloys、 Titanium Alloy

Machining Feature: More durable, easy to cut and drill, better impact resistance.

Recommended Parameter: Sigle – sided cutting depth: 0.5-2mm

-

VNMG Meiwha CNC Turning Inserts Series

Groove Profile: Fine/semi – fine processing

Applicable To: HRC: 20-40

Work Material: 40#steel, 50#forged steel, spring steel, 42CR, 40CR, H13 and other common steel parts.

Machining Feature: The special chip – breaking groove design avoids the phenomenon of chip entanglement during the processing and is suitable for continuous processing under harsh conditions.

-

DNMG Meiwha CNC Turning Inserts Series

Groove Profile: Special for steel

Work Material: Steel pieces ranging from 20degrees to 45degrees, including to 45 degrees, including A3 steel, 45#steel, spring steel, and mold steel.

Machining Feature: Special chip – breaking groove design, smooth chip removal, smooth processing without burrs, high glossiness.

-

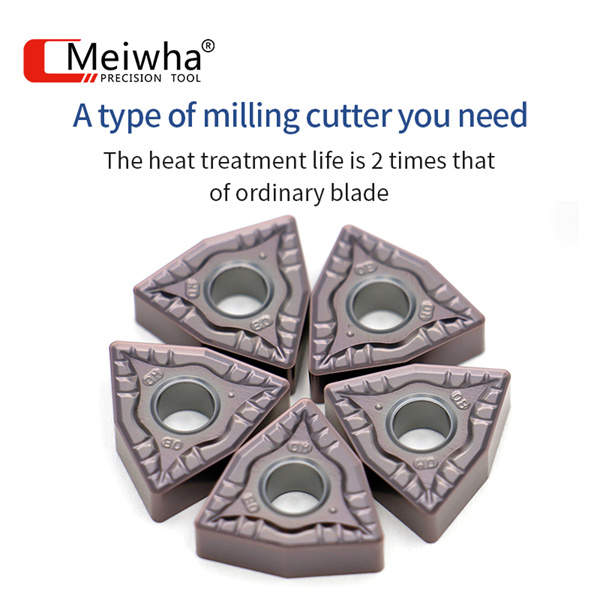

Meiwha APMT Milling Inserts

High Quality Material: Made of high quality carbide tips, exquisite workmanship, high strength, high toughness, stable and durable in use. Correct cutting effect, lower cutting force and longer tool life.

Exquisite workmanship: these rotary tools have metallic surface processing, good wear and tear.

Wide Application: Carbide inserts are mainly used for machining normal steel and normal stainless steel. They are suitable for turning and milling carbon and alloy steel, mould steel and stainless steel. -

Meiwha LNMU Milling Inserts

1.Machining steel parts and iron. PMKSH, For shoulder milling, face milling and slotting.

2.Type: Fast feed milling inserts.

Hardness: HRC15°-55°, quenched carbide inserts.

3.Good toughness and hardness; improve the surface gloss of the cutting preces.

4.High vibration-absorbing performance, improve the surface finish of the workpiece, Great for shoulder milling, face milling and slotting.

-

High End CNC Inserts

This High End CNC blade made of high quality tungsten steel with high wear resistance, low expansion efficient, and good corrosion resistance.

-

For Steel & Iron Casting

ISO standard tools perform most of the metalworking industry’s machining. The applications range from finishing to roughing.

-

For Stainless Steel & Titanium Alloy

ISO standard tools perform most of the metalworking industry’s machining. The applications range from finishing to roughing.

-

For Heat-Resistant Alloy

ISO standard tools perform most of the metalworking industry’s machining. The applications range from finishing to roughing.

-

For Aluminium & Copper

ISO standard tools perform most of the metalworking industry’s machining. The applications range from finishing to roughing.