Angle Head Holder

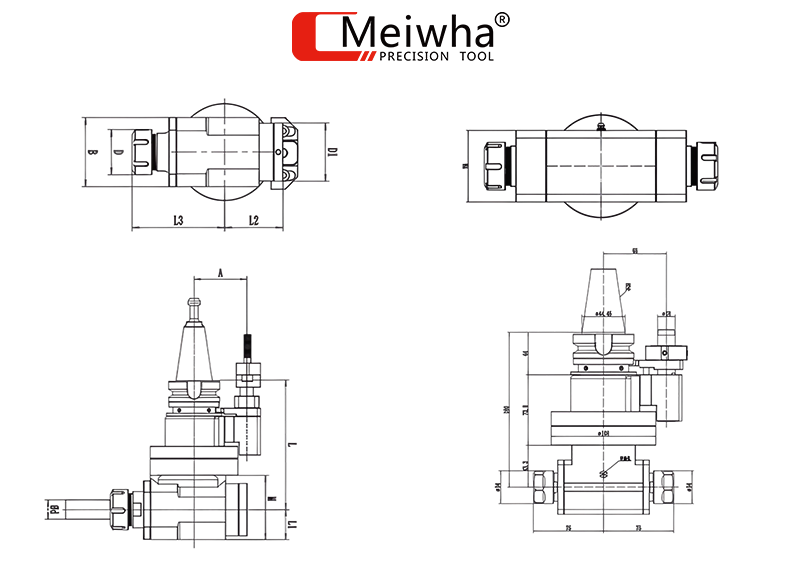

| Cat.No | Clamping range | A | L | L1 | L2 | L3 | M | D | D1 | B | |

| BT/BBT30 | -AMER25-130L | 2.0-16.0 | 50 | 130 | 23 | 49 | 81 | 62 | 42 | 64 | 46 |

| BT/BBT40 | -AMER20-160L | 2.0-13.0 | 65 | 160 | 37 | 65 | 102 | 79 | 50 | 64 | 77 |

| -AMER25-160L | 2.0-16.0 | 65 | 160 | 37 | 65 | 102 | 79 | 50 | 64 | 77 | |

| -AMER32-160L | 2.0-20.0 | 65 | 160 | 37 | 65 | 102 | 79 | 50 | 64 | 77 | |

| -AMER40-160L | 2.0-26.0 | 65 | 160 | 37 | 65 | 102 | 79 | 50 | 64 | 77 | |

| -AMER32-160-2 | 3.0-20.0 | -- | 160 | 65 | 130 | 260 | -- | 108 | 50 | 74 | |

| BT/BBT50 | -AMER20-170L | 2.0-13.0 | 80 | 170 | 37 | 65 | 102 | 79 | 50 | 64 | 77 |

| -AMER25-170L | 2.0-16.0 | 80 | 170 | 37 | 65 | 102 | 79 | 50 | 64 | 77 | |

| -AMER32-170L | 2.0-20.0 | 80 | 170 | 37 | 65 | 102 | 79 | 50 | 64 | 77 | |

| -AMER40-170L | 2.0-26.0 | 80 | 170 | 37 | 65 | 102 | 79 | 50 | 64 | 77 | |

| -AMER32-170-2 | 3.0-20.0 | -- | 170 | 80 | 142 | 284 | -- | 108 | 63 | 74 | |

Angle head holder Application:

1. Meiwha Angle Head Holder is used when it is difficult to fix large workpieces, when precision workpieces are fixed at one time and polyhedron need to be processed, when processing at any angle relative to the reference surface

2. The processing is maintained at a special angle for profling milling, such as ball end milling, other tools cannot penetrate the hole to process the small hole without Meiwha Angle Head Holder.

3. Obligue holes and grooves that cannot be processed by the machining center without Meiwha Angle Head Holder, such as the internal holes of the engine and the casing.

Angle head holder Precautions:

1. General angle heads use non-contact oil seals. lf cooling water is used during processing, it needs to be operated before spraying water, and the direction of the cooling water nozzle should be adlusted to spray water toward the tool to prevent cooling water from penetrating into the body. In order to prolong life.

2. Avoid continuous processing and operation at the highest speed for a long time.

3. Refer to the parameter characteristics of the angle head of each model and use it under appropriate processing conditions.

4. Before use, you need to confirm the test run for a few minutes to warm up the engine. Every time you process you need to select the appropriate speed and feed for processing. The speed, feed, and depth of cut during processing should be adjusted in a manner until the maximum processing efficiency is obtained

5.When processing with the general standard angle head. it is necessary to avoid processing materials that will produce dust and particles (such as. graphite, carbon, magnesium and other composite materials, etc.)

Side Milling Series

Meiwha90° Side Milling Head

Can be stored in tool magazine, Automatic tool changing, precision milling

High Rigidity Large Torque

When encountering materials with higher hardness during processing, the angle head can better maintain accuracy and stable rotation.

Automatic Tool Changing Precision Milling

Lightweight design, capable of automatic tool changing by storing in magazine.

Angle Head Classification

Structure Type:

Single output, dual output, quad output, adjustable, inclined, offset nonstandard.

Clamping Type:

Collet type, holder type, side clamping type, face milling type.

Installation type:

Fixed bracket type, flange type, four latin link plate type.

The Function of The Angle Head

1.Precis workpieces, one-time positioning, five - sided machine, ensuring accuracy.

2.Large workpieces, multi - face processing, enhanced efficiency.

3.Carry out processing of any angle on inclined surfaces, angles or holes.

4.Hole within a hole: can be machined using offset, seven - pointed angle heads.

5.Narrow grooves and inclined grooves can be machined using offset universal angle heads.