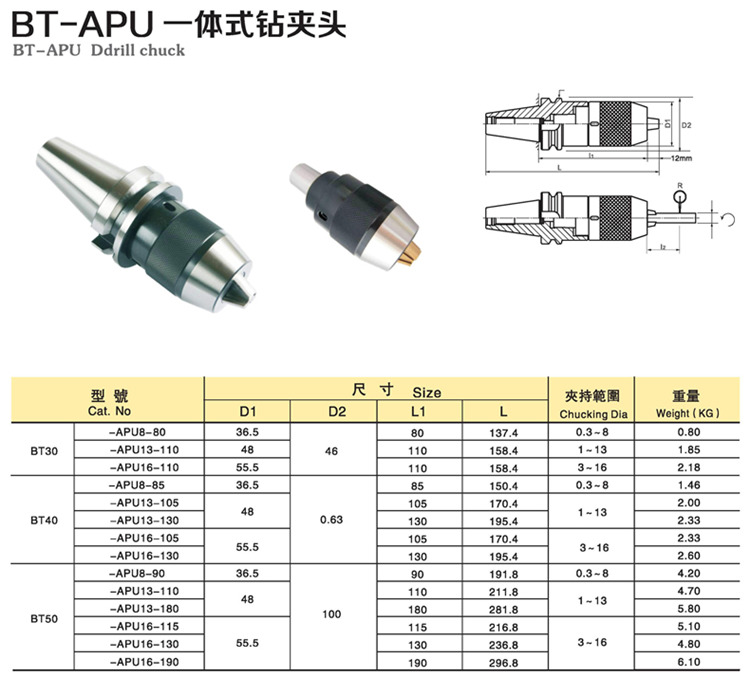

BT-APU Integrated Drill Chuck

There are three types of Meihua CNC BT tool holder: BT30 tool holder, BT40 tool holder, BT50 tool holder.

The material: using titanium alloy 20CrMnTi, wear-resistant and durable. The hardness of the handle is 58-60 degrees, the accuracy is 0.002mm to 0.005mm, the clamping is tight, and the stability is high.

Features: Good rigidity, high hardness, carbonitriding treatment, wear resistance and durability. High precision, good dynamic balance performance and strong stability. The BT tool holder is mainly used for clamping the tool holder and the tool in drilling, milling, reaming, tapping and grinding. Choose high-quality materials, after heat treatment, it has good elasticity and wear resistance, high precision and stable performance.

During machining, specific demands for tool holding are laid down by each industry and application. The range varies from high-speed cutting to heavy roughing.

With the MEIWHA tool holders, We offers the right solution and tool clamping technology for all specific requirements. Therefore, each year we invest approximately 10 percent of our turnover in research and development.

Our primary interest is to offer our customers sustainable solutions which enable a competitive advantage. This way, you can always maintain your competitive advantage in machining.