Self Centering Vise: A Precision Clamping Revolution From Aerospace To Medical Manufacturing

A practical solution with a 0.005mm repeat accuracy, 300% improvement in vibration resistance, and a 50% reduction in maintenance costs.

Article Outline:

I. Self centering Vise: The Revolutionary Value of Disrupting Traditional Clamping

Case 1: A well-known automotive component manufacturer

The main problems encountered when using the vise:

1.Large concentricity deviation: The traditional vise clamping method results in a concentricity error of the gear of 0.03mm, which exceeds the tolerance range (≤0.01mm), and the scrap rate is as high as 15%.

2. Low production efficiency: Each piece requires 8 minutes for clamping, and frequent adjustments disrupt the production line rhythm.

3.Surface quality instability: The processing vibration causes the surface roughness Ra to fluctuate between 0.6 and 1.2 μm, resulting in a 30% increase in polishing costs.

Solution: Upgrade of self-centering vise technology

Core parameters of the Self Centering Vise:

Centering accuracy: ±0.005mm

Repeatability positioning accuracy: ±0.002mm

Maximum clamping force: 8000N

Hardened guide rails (HRC ≥ 60) anti-wear capability

(These points can all be met by the Meiwha self centering vise.)

Specific implementation steps for replacing the self centering vise:

1. Production line renovation: Replace the traditional vices on 5 machining centers and integrate the zero-point quick-change system

2. Self centering vise with shark fin-like jaw design: The special tooth shape enhances friction, reducing cutting vibration (vibration amplitude is reduced by 60%)

The breakthroughs achieved in terms of precision, efficiency and cost after upgrading the self centering vise.

| Index | Before upgrading the Self centering vise | After upgrading the self centering vise | Improvement percentage |

| Coaxial error | 0.03mm | 0.008mm | 73%↓ |

| Single-piece clamping time | 8min | 2min | 75%↓ |

| Surface roughness Ra | 0.6-1.2μm | Stability ≤ 0.4 μm | consistency |

| Annual waste loss | ¥1,800,000 | $450,000 | ¥1.35 million saved |

| Cutting life | On average, 300 items. | 420items | 40%↑ |

Cost recovery for self centering vise update: Equipment investment is ¥200,000, and the cost is recovered within 6 months.

II. Core Advantages of the Self centering vise Clamps: A Triple Breakthrough in Precision, Efficiency and Flexibility

Advantage of self centering vise 1: Micrometer-level accuracy guarantee

Bidirectional screw rod synchronization technology: Eliminates unilateral offset, repeatability positioning accuracy ≤ 0.005mm (video of dial indicator test)

Comparison data of vibration resistance between self centering vise and traditional vise

| Clamping method | Vibration amplitude (μm) | Surface roughness Ra (μm) |

| Traditional vise | 35 | 1.6 |

| Self centering vice | 8 | 0.4 |

Self centering vise advantage 2: Efficiency doubled by engine

Self centering vise Quick Change System:

Zero-point positioning enables a 2-second switch of workpieces

The modular jaws support the simultaneous clamping of multiple sets of workpieces during processing.

Space utilization increased by 40%: Low center, high design (100 - 160mm), enabling 5 workpieces to be processed simultaneously

Self centering vise grips advantage 3: Core of flexible production

Universal adaptability:

Hard claws: Clamping steel parts / castings (compatible with rough surfaces)

Soft Claws: Customized Silicone Jaw Covers for Protecting the Surface of Medical Implants

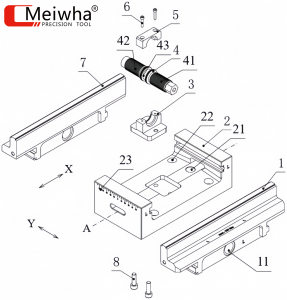

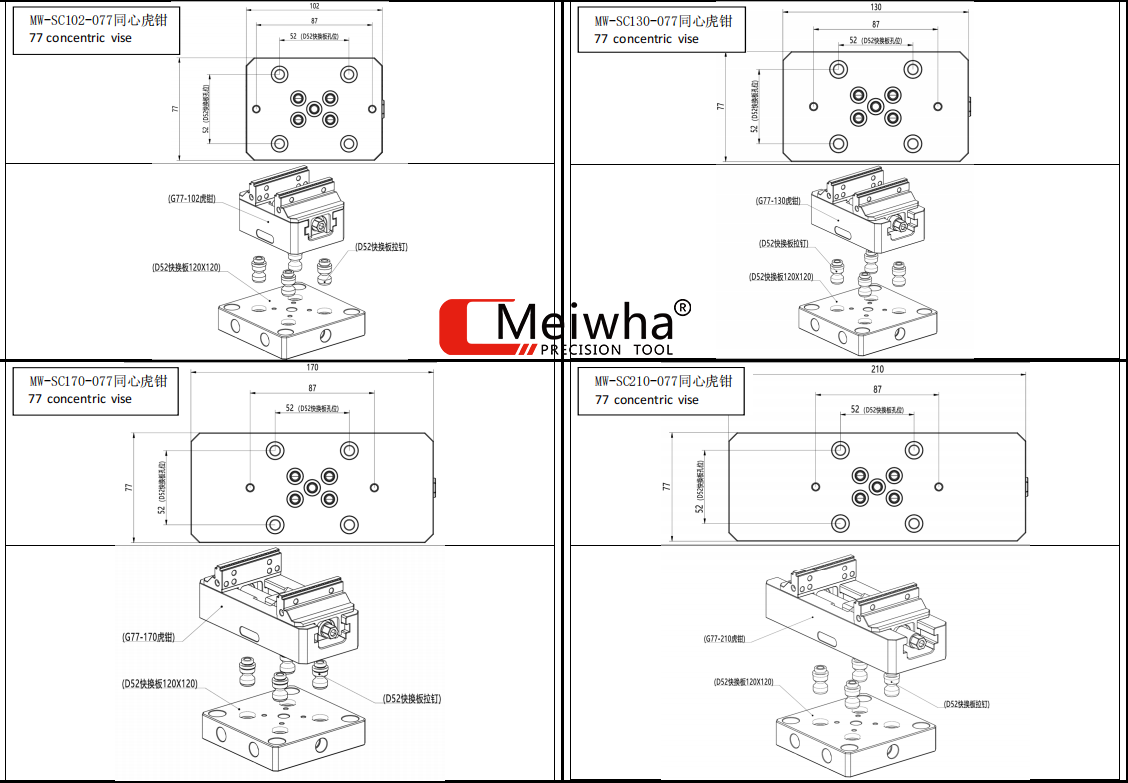

Self Centering Vise Scheme Layout Diagram

III. Six Application Scenarios and Selection Examples of Self centering vise

| Industry | Typical workpiece | Sikution | Effect |

| Aerospace | Titanium alloy wing ribs | High-frequency induction heating vise + ceramic-coated jaws | Deformation < 0.01mm, tool life doubled |

| Medical implantation | Knee Prosthesis | Pneumatic self centering vise + Medical-grade soft jaws | Surface has no scratches, yield rate → 99.8% |

| New energy automobile | Battery box body | Strengthened rigid hydraulic vise (anti-vibration model) | The processing vibration is reduced by 60%, and the working time is decreased by 35%. |

| Precision electronics | Mobile phone middle frame | Miniature self centering vise ( φ80mm stroke) | Area reduced by 70%, accuracy ±0.003mm |

IV. Maintenance Guide for Self Centering Vise : Can Extend Self Centering Vise's Service Life

1.Daily Maintenance Checklist for Vice Grips:

| Self centering vise components | Work standards |

| Lead screw guide rail | Daily air gun dust removal + Weekly grease injection |

| Clamping surface contact area | Alcohol wiping off the remaining cutting fluid |

| Driving mechanism | Monthly inspection of the gas path sealing performance (pressure ≥ 0.6 MPa) |

2. Three do's and don'ts for maintaining self centering vise

1.Use a metal brush to clean the guide rail → cause scratches on the precision surface

2. Mixing lubricants of different viscosities → Will lead to gelation and blockage

3. Exceeding the rated clamping force by 50% → will result in permanent deformation

Post time: Aug-09-2025