In the modern field of automated production and material handling, vacuum chucks have become a key tool for enhancing efficiency and reducing labor costs. Relying on the principle of vacuum negative pressure, they can firmly adhere to workpieces of various materials and shapes, enabling high-speed, precise, and safe handling operations. From glass panels, metal sheets, to plastic products and cardboard boxes, vacuum chucks can handle them all with ease, and are widely used in industries such as electronics manufacturing, automotive production, and logistics packaging.

In the modern field of automated production and material handling, vacuum chucks have become a key tool for enhancing efficiency and reducing labor costs. Relying on the principle of vacuum negative pressure, they can firmly adhere to workpieces of various materials and shapes, enabling high-speed, precise, and safe handling operations. From glass panels, metal sheets, to plastic products and cardboard boxes, vacuum chucks can handle them all with ease, and are widely used in industries such as electronics manufacturing, automotive production, and logistics packaging.

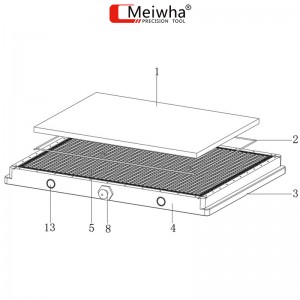

Meiwha Vacuum Chuck

I. The Working Principle of the Vacuum Chuck

The working principle of a vacuum chuck is based on the difference in atmospheric pressure. In simple terms, it creates a low-pressure (vacuum) area artificially, and uses the pressure difference between the external normal atmospheric pressure and the internal low pressure to generate an adhesive force, thereby "sucking" the object in.

Vacuum chuck operation process:

1.Sealed contact: The lip edge of the chuck (usually made of elastic materials such as rubber, silicone, polyurethane, etc.) comes into contact with the surface of the object being adsorbed, forming an initial, relatively sealed cavity (the internal space of the chuck)

2.Vacuuming: The vacuum generator connected to the chuck (such as a vacuum pump, Venturi tube/vacuum generator) starts to operate.

3.Create pressure difference: As the air is being evacuated, the pressure within the chuck cavity rapidly decreases (forming a negative pressure/vacuum state).

At this moment, the atmospheric pressure outside the chuck (approximately 101.3 kPa / 1 Bar) is much greater than the pressure inside the chuck.

4.Generate adhesive force: This pressure difference (external atmospheric pressure - internal vacuum pressure) acts on the effective area where the chuck comes into contact with the object.

According to the formula, adsorption force (F) = pressure difference (ΔP) × effective adsorption area (A), a force perpendicular to the surface of the object (adsorption force) is generated, firmly "pressing" the object onto the chuck.

5.Maintain adsorption: The vacuum generator operates continuously or maintains the vacuum level inside the chuck through the one-way valve in the vacuum circuit or the vacuum storage tank, thereby maintaining the adhesion force.

6.Release the workpiece: When it is necessary to release the object, the control system will shut off the vacuum source. Usually, the ambient air is reintroduced into the chuck chamber through a broken vacuum valve. The pressure inside and outside the chuck returns to equilibrium (both at atmospheric pressure), the adhesive force disappears, and the object can then be released.

From this, it can be concluded that the key elements of the vacuum chuck in holding the workpiece are:

1.Sealing property: The good sealing between the chuck lip and the surface of the object is a prerequisite for forming an effective vacuum chamber. The surface of the object needs to be relatively smooth, flat, and non-permeable (or with no micropores).

2.Vacuum Degree: The vacuum level (negative pressure value) that can be achieved inside the chuck directly affects the strength of the adsorption force. The higher the vacuum degree, the greater the adsorption force.

3.Effective Adsorption Area: The area within the lip edge of the chuck that actually comes into contact with the object. The larger the area, the greater the adsorption force.

4.Material Adaptability: The chuck material must be able to adapt to the surface characteristics of the object being grasped (smooth, rough, porous, oily, etc.) as well as the environment (temperature, chemical substances).

CNC Vacuum Chuck

II. Maintenance methods for vacuum chucks:

1.Daily inspection and cleaning:

Cleaning the surface of the vacuum chuck: Before and after each use or at regular intervals (depending on the working conditions), use a clean soft cloth or non-woven fabric dipped in water or neutral cleaner to wipe the lip edge and working surface of the suction cup. Do not use organic solvents (such as acetone, gasoline), strong acid or strong base cleaners, as they will corrode the rubber material, causing hardening and cracking.

Remove foreign objects: Inspect and remove dust, debris, oil stains, cutting fluids, welding slag, etc. from the lip edge of the suction cup, the internal channels, and the surface of the object being sucked. These can damage the sealing performance.

Check for sealing integrity: Examine visually for any damage, cracks, scratches, or deformations on the lip edge of the chuck. When attaching the object, listen carefully for any obvious air leakage sounds and observe whether the vacuum gauge reading can quickly reach and maintain the target value.

2.Regular in-depth inspection:

Check for wear: Carefully inspect the lips of the vacuum chuck, especially the edges that come into contact with the object. Are there any signs of excessive wear such as thinning, flattening, fraying, or nicks? Wear can significantly reduce the sealing and adhesion properties.

Check for aging: Observe whether the chuck material has become hard, brittle, lost elasticity, developed cracks, or shown significant discoloration (such as turning yellow or white). This is a sign of material aging.

Check the connections: Ensure that the chucks are securely fastened to the chuck holders, and that the chuck holders are securely connected to the vacuum piping, with no looseness or air leakage. Also, check if the quick connectors are in good condition.

Inspect the vacuum piping: Check whether the vacuum hose connecting the chuck is aged (becoming hard, cracking), flattened, bent, clogged or damaged with air leakage.

3.Replacement and Maintenance:

Replace in time: If you find that the vacuum vacuum chuck is excessively worn, damaged, severely aged, permanently deformed, or has stubborn stains that are difficult to clean, you should replace it immediately. Do not attempt to repair the damaged chuck, as this may lead to safety hazards and unstable performance. Generally, it is recommended to set a regular replacement schedule based on usage frequency and working conditions (such as every 3-6 months or more frequently).

Spare parts reserve: Maintain a stock of spare parts for commonly used chucks to reduce downtime.

Correct installation: When replacing the vacuum chuck, ensure proper installation, with moderate tightening force (avoiding excessive tightness which may damage the chuck or insufficient force which may cause air leakage), and the connecting pipeline should be free from distortion.

Storage: The backup chuck should be stored in a cool, dry, and dark place, away from heat sources, ozone sources (such as motors, high-voltage equipment), and chemicals. Avoid squeezing or deforming.

4.Preventive Maintenance and Fault Resolution:

Matching selection: Select the appropriate type of vacuum chuck (flat, corrugated, elliptical, sponge suction cup, etc.), material (NBR nitrile rubber, silicone, polyurethane, fluororubber, etc.) and size based on the weight, size, material, surface condition, and environmental conditions (temperature, chemical environment) of the object being captured.

Avoid overloading: Ensure that the adhesion force (considering the safety factor, usually more than twice the normal value) is sufficient to grasp the object, and avoid keeping the chuck in an extreme load state for a long time.

Avoid extreme conditions: Avoid leaving the vacuum chuck exposed to excessively high temperatures (above the material's tolerance limit), strong ultraviolet rays, ozone, or corrosive chemicals for an extended period of time.

Avoid hard impacts/scrapes: During programming or operation, ensure that the chuck does not exert excessive force to collide with the workpiece or the table surface, and avoid being scratched by sharp objects.

Meiwha Vacuum Chuck

III. Fault diagnosis of vacuum chuck: When the adhesion force decreases or the fails to hold the object, you should conduct an investigation

The chuck body (wear and tear, damage, aging, dirtiness)

Sealing ring / Joint (leaking)

Vacuum piping (damaged, clogged, leaking)

Vacuum generator/pump (performance decline, filter clogging)

Vacuum switch/sensor (fault)

Vacuum break valve (leaking or not closed)

The surface of the object being sucked (porous, uneven, oily, breathable)

IV. Common Problems of Vacuum Chucks:

1.The vacuum chuck is unable to attach to those objects?

Breathable materials, extreme surface defects, adhesive surfaces

2.What is the difference between a vacuum chuck and an electromagnetic chuck?

| Character | Vacuum Chuck | Electromagnetic Chuck |

| Working Principle | Atmospheric pressure difference adsorption | The electromagnetic field magnetizes ferromagnetic materials, thereby generating suction. |

| Applicable Materials | All solids (with the surface sealed) | Only ferromagnetic metals (such as steel, iron, etc.) |

| Energy Consumption | It requires continuous vacuuming (with high energy consumption) | It consumes energy only during the initial power-on period, and has low energy consumption during the subsequent operation. |

| Security | Power failure can still maintain adsorption (requires vacuum breakdown) | Power failure causes immediate loss of force (objects may fall) |

| Surface Requirement | Afraid of oil stains and dust (which can damage the seal) | Not afraid of oil stains, but the air gap will weaken the magnetic force. |

|

Temperature Limitation |

High-temperature resistant material (silicone/fluorine rubber) | High temperature is prone to demagnetization (usually below 150℃) |

| Application Scenarios | Glass, plastic, food, electronics, etc. | Machine tool fixtures, steel handling |

Vacuum chuck, as an important functional component in modern automated handling and production systems, have demonstrated their advantages such as high efficiency, safety, and wide applicability. As a result, they have played an irreplaceable role in fields like electronic manufacturing, automotive industry, packaging logistics, etc. Through proper selection and scientific maintenance, vacuum chucks can not only significantly enhance production efficiency but also reduce equipment wear and operational costs.

If you are looking for a stable, long-lasting and cost-effective vacuum chuck solution, we can offer you a one-stop service including selection guidance, customized design and after-sales support.

Contact our technical team immediately to obtain a free solution assessment and personalized quote, and make your production system more efficient and reliable!

Post time: Aug-15-2025