In order to improve the product knowledge ability of New employee, Meiwha Industry Association held the 2023 annual product knowledge training activity, and launch series of training for all Meiwha Products.

As one qualified Meiwha person , It must be more clearly knowledge about tool Holders ,Inserts and Milling Taps, Drills , Boring Grinder Machines and other relevant product,Let's also summarize the content of this training,

The CNC tool holder has been designed to securely hold all kinds of cutting tools while they are being moved back-and-forth during machining operations. With its ability to quickly change out different size cutters, this device can make a huge difference in time saved and efficiency gained when operating machinery such as lathes or milling machines. It should have adjustable stops so operators know exactly where their cuts begin and end every time–increasing accuracy levels significantly.The tool handle is the connecting body of the machine tool and the tool. The tool handle is a key link affecting the concentricity and dynamic balance. It must not be regarded as a general component. Concentricity can determine whether the cutting amount of each cutting edge part is uniform under the condition of one rotation of the tool; When the spindle rotates, the dynamic imbalance will produce periodic vibration

Meiwha Holder, commonly used types We divided into BT-ER Holder, BT-C strong Holder, FMB-FMA Face Milling Cutter Holder, BT-MTA Mose taper sleeve, BT-SK High speed sk collet chuck, BT-APU Drill chuck, BT-HM Hydraulic expansion chuck, BT-SR Shrink fit chuck

For commonly used CNC milling tools, according to the shape, divide into flat inserts, round nose inserts and ball inserts

Each tool has its specific role, the specific as follows:

1) flat inserts CNC machining center flat inserts inserts is also called flat inserts or end milling cutter, around the main cutting edge, the bottom for the secondary cutting edge. Can be used for rough and clear Angle, finish the side plane and horizontal plane. Commonly used are ED20, ED19.05 (3/4 inch), ED16, ED15.875 (5/8 inch), ED12, ED10, ED8, ED6, ED4, ED3, ED2, ED1.5, ED1, ED0.8 and ED0.5. E is the first letter of End Mill; D represents cutting edge diameter. Under normal circumstances, try to choose a large diameter inserts when opening thick, and as short as possible when loading the inserts, in order to ensure sufficient stiffness and avoid spring inserts. When choosing a inserts, it is necessary to combine the processing area, determine the shortest blade length and the length of the straight part, and choose the most suitable inserts available in the company. If the side slope is called the slope inserts, you can finish the slope.

2) Round nose inserts CNC machining center round nose inserts, also called flat R inserts, can be used to open rough, flat and curved shape inserts. Generally, the angular radius is R0.1 ~ R8. There are generally integral and insert blade blade. The round nose inserts with insert grain is also called "flying inserts", which is mainly used for large area of opening rough and horizontal smooth inserts. Commonly used are ED30R5, ED25R5, ED16R0.8, ED12R0.8 and ED12R0.4. As far as possible, large inserts should be selected for rough machining of flying inserts. When processing deeper areas, the length of the tool should be installed first for short processing shallower areas, and then for long processing deeper areas, so as to improve efficiency and not cut.

3) The ball inserts CNC machining center of the ball inserts is also called R inserts, mainly used for curved surface in the light inserts and light inserts. Commonly used ball knives are BD16R8, BD12R6, BD10R5, BD8R4, BD6R3, BD5R2.5 (often used for processing runner), BD4R2, BD3R1.5, BD2R1, BD1.5R0.75 and BD1R0.5. B is the first letter of Ball Mill. Under normal circumstances, by measuring the inner circle radius of the processed figure to determine the tool used for finishing, as far as possible to choose a large inserts, inserts repair inserts processing

one milling cutter is a rotary cutter having one or more cutter teeth for milling. When working, each cutter tooth successively intermittently cuts off the workpiece's margin. Milling cutter is mainly used in milling machine processing plane, step, groove, forming surface and cutting work-piece.

Milling cutter is divided into flat end milling cutter, ball end milling cutter, round nose milling cutter, aluminum milling cutter

4.Taps

Tap is one tool for processing various medium and small size internal threads. It is simple in structure and easy to use. It can be operated manually and can also be worked on machine tools

What is tapping

Tapping is the use of taps to cut internal threads in the hole of the work-piece.

Taps divide into Straight Spirals Tap,Flute Tap, Tip Tap, and Extrusion Tap

5.Drill

The drill is a cutting tool in a drill used to remove material to form a hole and almost always has a circular cross section. Drill bits come in a variety of sizes and shapes and can form different types of holes in many different materials. In order to punch a hole, the drill bit is usually attached to the drill bit, which is usually rotated to provide power to cut the workpiece. The bit will grasp the upper end of the bit called the shank in the chuck.

According to different materials of the workpiece, we can divide Drill bits into HSS Drill, Alloy Drill, Twist Drill and Carbide Drill

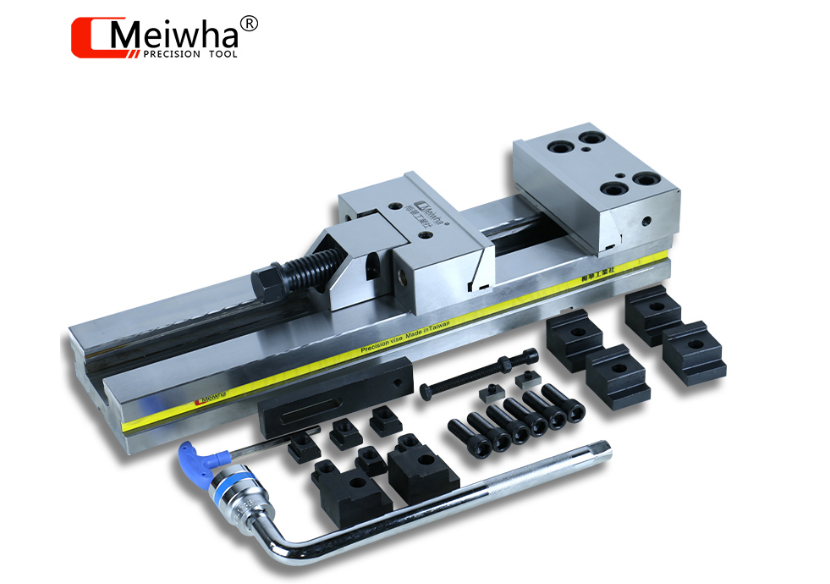

One vise is a universal fixture used to hold a work piece. The device is on the workbench to clamp and stabilize the workpiece. It is a necessary tool for the fitter workshop. The rotary disc clamp body can be rotated to rotate the workpiece to the appropriate working position

We have High power Hydraulic Vise and MC Compact Power Vise and Angle solid vise.

For machining operators, if the tool is worn in the process of use, it can be used to grind the tool, so that the blade can continue to be used to meet the accuracy requirements of the workpiece

We have Mill Sharpener, Tap Sharpener, Drill Sharpener three kinds of Grinder machine

Milling cutters, taps and drill bits can be ground

7.Sucker

The workpiece is adsorbed on the surface of the disk to fix, and the machine cutting,

We have Integrated CNC Vacuum Sucker, CNC Powerfull Permanennt Magenet Sucker,CNC Electro-Permanent Magnetic Chucks, three kinds of Sucker

Post time: Feb-24-2023