A high-efficiency milling cutter can complete three times the workload of ordinary tools in the same amount of time while reducing energy consumption by 20%. This is not only a technological victory, but also a survival rule for modern manufacturing.

In machining workshops, the unique sound of rotating milling cutters coming into contact with metal constitutes the basic melody of modern manufacturing.

This rotating tool with multiple cutting edges shapes everything from tiny cell phone parts to giant aircraft structures by precisely removing material from the workpiece surface.

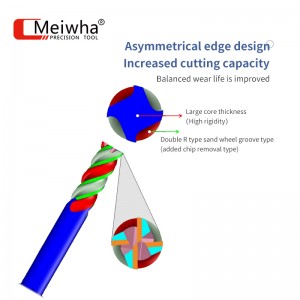

As the manufacturing industry continues to upgrade towards high precision and high efficiency, milling cutter technology is undergoing a silent revolution - the bionic structure milling cutter manufactured by 3D printing technology is 60% lighter, but its lifespan is more than doubled; the coating extends the life of the tool by 200% when processing high-temperature alloys.

I. Milling cutter basics: definition and core value

A milling cutter is a rotating tool with one or more teeth, each of which sequentially and intermittently removes the workpiece stock. As a core tool in milling, it performs critical tasks such as machining planes, steps, grooves, forming surfaces, and cutting off workpieces.

Unlike single-point cutting in turning, milling cutters significantly improve machining efficiency by cutting at multiple points simultaneously. Its performance directly affects workpiece accuracy, surface finish, and production efficiency. In the aerospace field, a high-performance milling cutter can save up to 25% of production time when machining aircraft structural parts.

In automobile manufacturing, precision form milling cutters directly determine the fitting accuracy of key engine components.

The core value of milling cutters lies in their perfect combination of versatility and efficiency. From rapid material removal in roughing to surface treatment in fine machining, these tasks can be completed on the same machine tool by simply changing different milling cutters, significantly reducing equipment investment and production changeover time.

II. Historical context: technological evolution of milling cutters

The development history of milling cutters reflects the technological changes in the entire machinery manufacturing industry:

1783: French engineer René created the world's first milling cutter, opening a new era of multi-tooth rotary cutting.

1868: Tungsten alloy tool steel came into being, and cutting speed exceeded 8 meters per minute for the first time.

1889: Ingersoll invented the revolutionary corn milling cutter (spiral milling cutter), inlaying the blade into the oak cutter body, which became the prototype of the modern corn milling cutter.

1923: Germany invented cemented carbide, which increased the cutting speed by more than twice that of high-speed steel.

1969: Patent for chemical vapor deposition coating technology was issued, increasing tool life by 1-3 times.

2025: Metal 3D-printed bionic milling cutters achieve a 60% weight reduction and double their lifespan, breaking through traditional performance boundaries.

Every innovation in materials and structures drives geometric growth in milling efficiency.

III. Comprehensive analysis of milling cutter classification and application scenarios

According to the differences in structure and function, milling cutters can be divided into the following types:

|

Type |

Structural characteristics | Applicable Scenarios | Application Industry |

| End mills | Cutting edges on both circumference and end faces | Groove and step surface processing | Mold manufacturing, general machinery |

| Face milling cutter | Large diameter multi-blade end face | Large surface high-speed milling | Automobile cylinder block and box parts |

| Side and face milling cutter | There are teeth on both sides and circumference | Precision groove and step processing | Hydraulic valve block, guide rail |

| Ball end mills | Hemispherical cutting end | 3D surface processing | Aviation blades, mold cavities |

| Corn milling cutter | Spiral arrangement of inserts, large chip space | Heavy shoulder milling, deep grooving | Aerospace structural parts |

| Saw blade milling cutter | Thin slices with multiple teeth and secondary deflection angles on both sides | Deep grooving and parting | Thin slices with multiple teeth and secondary deflection angles on both sides |

Structural type determines economy and performance

Integral milling cutter: The cutter body and teeth are integrally formed, with good rigidity, suitable for small diameter precision machining

Indexable milling cutters: cost-effective replacement of inserts rather than the entire tool, suitable for roughing

Welded milling cutter: carbide tip welded to steel body, economical but limited regrinding times

3D printed bionic structure: internal honeycomb lattice design, 60% weight reduction, improved vibration resistance

IV. Scientific Selection Guide: Key Parameters Matching Processing Requirements

Choosing a milling cutter is like a doctor prescribing a prescription - you must prescribe the right medicine for the right condition. The following are the key technical factors for selection:

1. Diameter matching

Cutting depth ≤ 1/2 tool diameter to avoid overheating and deformation. When processing thin-walled aluminum alloy parts, it is advisable to use a small diameter end mill to reduce cutting force.

2. Blade length and number of blades

Cutting depth ≤ 2/3 of the blade length; for roughing, select 4 or fewer blades to ensure chip space, and for finishing, select 6-8 blades to improve surface quality.

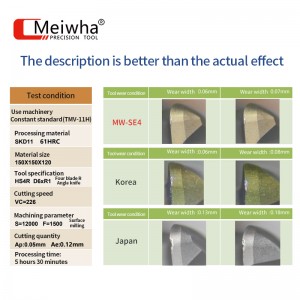

3. Evolution of tool materials

High-speed steel: high toughness, suitable for interrupted cutting

Cemented carbide: mainstream choice, balanced hardness and toughness

Ceramics/PCBN: Precision machining of superhard materials, first choice for hardened steel

HIPIMS coating: New PVD coating reduces built-up edge and extends life by 200%

4. Geometric parameter optimization

Helix angle: When processing stainless steel, choose a small helix angle (15°) to increase the edge strength.

Tip Angle: For hard materials, choose a large angle (>90°) to enhance support

Today's engineers are still challenged by a timeless question: how to make metal cutting as smooth as flowing water. The answer lies in the sparks of wisdom colliding between the spinning blade and the ingenuity.

[Contact us for cutting and milling cutter solutions]

Post time: Aug-17-2025