End Milling for Aluminum HSS Milling Cutter for Aluminum 6mm – 20mm

Titanium aluminum nitride (AlTiN or TiAlN) coatings are slippery enough to help keep chips moving, especially if you aren’t using coolant. This coating is often used on carbide tooling. If you’re using high-speed steel (HSS) tooling, look for coatings like titanium carbo-nitride (TiCN). That way you get the lubricity needed for aluminum, but you can spend a little less cash than on carbide.

· DLC coating (diamond-like coating)-The tool surface to obtain ultra-high hardness(HV7000) Low coefficient of friction(μ=0.08-0.15),Strong adhesion resistance.

· Use ultrafine grain tungsten steel matrix,Perfect combination of toughness and hardness,Improve wear resistance while avoiding breakage and fracture.

· Manufactured with five-axis precision grinding machine, Each milling cutter is tested by tool testing instruments,Good stability of dimensional accuracy.

· Unique cutting edge design, specially used in aluminum alloy, copper alloy processing.

· Greatly performance for alumimum / aerospace/new energy vehicle. U-groove type design for high feed rating and greatly surface finishing.

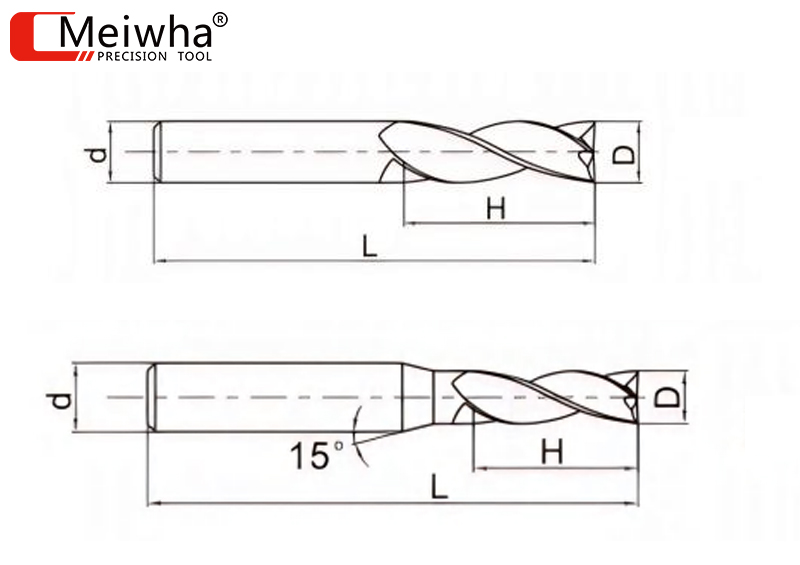

| Cat.No | Size | ||||

| Flutes | Outer dimaeter(D) | Blade Length(Lc) | Handle diameter(d) | Full length(L) | |

| FW3-D1-3H-d4-50L | 3 | 1 | 3 | 4 | 50 |

| FW3-D1.5-4H-d4-50L | 1.5 | 4 | |||

| FW3-D2-6H-d4-50L | 2 | ||||

| FW3-D2.5-7H-d4-50L | 2.5 | 7 | |||

| FW3-D3-9H-d4-50L | 3 | 9 | |||

| FW3-D3-9H-d6-50L | 6 | ||||

| FW3-D3.5-11H-d4-50L | 3.5 | 11 | 4 | ||

| FW3-D4-12H-d4-50L | 4 | 12 | |||

| FW3-D4-12H-d6-50L | 6 | ||||

| FW3-D5-13H-d6-50L | 5 | 13 | |||

| FW3-D5-20H-d6-75L | 20 | 75 | |||

| FW3-D6-18H-d6-50L | 6 | 18 | 50 | ||

| FW3-D6-25H-d6-75L | 25 | 75 | |||

| FW3-D8-20H-d8-60L | 8 | 20 | 8 | 60 | |

| FW3-D8-35H-d8-75L | 35 | 75 | |||

| FW3-D10-25H-d10-75L | 10 | 25 | 10 | ||

| FW3-D10-40H-d10-100L | 40 | 100 | |||

| FW3-D12-30H-d12-75L | 12 | 30 | 12 | 75 | |

| FW3-D12-50H-d12-100L | 50 | 100 | |||

| FW3-D16-80H-d16-150L | 16 | 80 | 16 | 150 | |