China Wholesale Din 352 HSS Thread Taps Factories - Spiral Flute Tap – MeiWha

China Wholesale Din 352 HSS Thread Taps Factories - Spiral Flute Tap – MeiWha Detail:

Following are recommendations for the degree of spiral for various materials:

Spiral flute taps are more suitable for processing non-through hole threads (also called blind holes), and the chips are upward during processing discharge. Due to the helix angle, the actual cutting rake angle of the tap will increase as the helix angle increases.

• High spiral flutes 45° and higher – effective for very ductile materials like aluminum and copper. If used in other materials, they will usually cause the chips to nest because the spiral is too • fast and the chip area is too small for the chip to form correctly.

• Spiral flutes 38° – 42° – recommended for medium to high carbon steel or free machining stainless steel. They form a chip tight enough to easily evacuate. On larger taps, it allows for pitch relief to ease the cutting.

• Spiral flutes 25° – 35° – recommended for free machining, low or leaded steels, free machining bronze, or brasses. Spiral flute taps used in brass and tough bronzes normally do not perform well because the small broken chip will not flow up the spiral flute well.

• Spiral flutes 5° – 20° – For tougher materials such as some stainless, titanium or high nickel alloys, a slower spiral is recommended. This allows the chips to be slightly pulled upward but does not weaken the cutting edge as much as higher spirals will.

• Reverse cut spirals, such as RH cut/LH spiral, will push the chips forward and are usually 15° spiral. These work especially well in tubing applications.

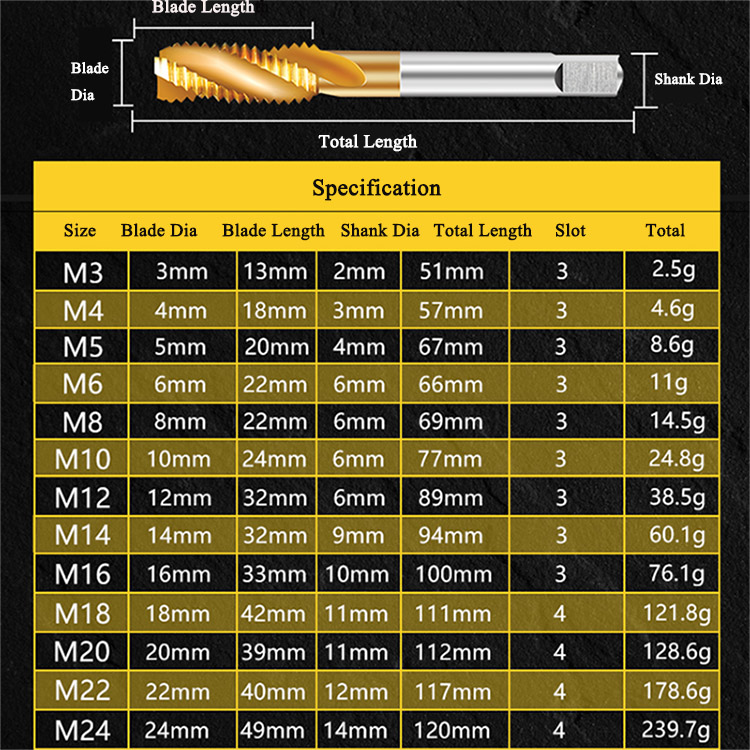

Product detail pictures:

Related Product Guide:

we are able to supply top quality items, aggressive price and greatest buyer assistance. Our destination is "You come here with difficulty and we offer you a smile to take away" for China Wholesale Din 352 HSS Thread Taps Factories - Spiral Flute Tap – MeiWha , The product will supply to all over the world, such as: Canada, Cape Town, Sri Lanka, Our domestic website's generated over 50, 000 purchasing orders every year and quite successful for internet shopping in Japan. We would be happy to have an opportunity to do business with your company. Looking forward to receiving your message !

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.