China Wholesale Drill Sharpening Machine Factory - HSS Drill – MeiWha

China Wholesale Drill Sharpening Machine Factory - HSS Drill – MeiWha Detail:

Meiwha Drill Tools offer HSS Drill and Alloy Drill.The HSS Twist Drill Bit Ground is for drilling through metal with maximum precision. The bit’s exposed 135-degree self-centring split-point tip combines active cutting and perfect centring without wandering, delivering maximum precision. The split-point tip also eliminates any need to pre-punch or pilot drill for up to 10 mm. This precision-ground bit made of HSS (high-speed steel) enables up to 40% faster drilling rate and up to 50% lower feed pressure than standard-ground HSS drill bits with chisel edges. This bit is designed for drilling holes in alloyed and non-alloyed steel, cast steel, cast iron, sintered iron, malleable cast iron, non-ferrous metals and hard plastics. It has a cylindrical shank system (shank equal to drill bit diameter) and is intended for use in drill stands and drill drivers.

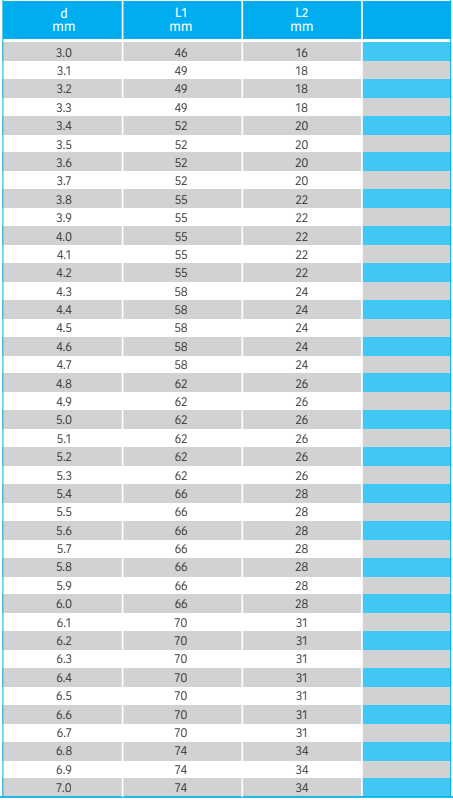

The HSS Twist Drill Bit Ground is manufactured to DIN 1897. The drill bit is Type N (flute angle) with a 118-degree tip and a diameter tolerance of h8.

Precautions for using cemented carbide tools

1) Cemented carbide is a hard and brittle material, which is brittle and damaged under excessive force or some specific local stress effects, and has sharp cutting edges.

2) Most of the cemented carbides are mainly tungsten and cobalt. The ingredients have a high density, so they should be handled as heavy objects during transportation and storage.

3) Cemented carbide and steel have different thermal expansion coefficients. In order to prevent stress concentration from cracking, attention should be paid to welding at an appropriate temperature.

4) Carbide cutting tools should be stored in a dry, away from corrosive atmosphere.

5) During the cutting process of cemented carbide tools, chips, chips, etc. cannot be prevented. Please prepare necessary labor protection supplies before machining.

6) If cooling fluid or dust collection equipment is used in the cutting process, in consideration of the service life of the machine tool and cutting tools, please use cutting fluid or dust collection equipment correctly.

7) Please stop using the tool with cracks during processing.

8) Carbide cutting tools will become dull and lose strength due to long-term use. Please don’t let non-professionals sharpen them.

9) Please keep the worn out alloy tools and the fragments of alloy tools properly to prevent damage to others.

Product detail pictures:

Related Product Guide:

Our pursuit and enterprise aim would be to "Always fulfill our buyer requirements". We carry on to acquire and layout excellent quality items for the two our old and new clients and realize a win-win prospect for our shoppers in addition as us for China Wholesale Drill Sharpening Machine Factory - HSS Drill – MeiWha , The product will supply to all over the world, such as: Swiss, Austria, Costa rica, Besides strong technical strength, we also introduce advanced equipment for inspection and conduct strict management. All the staff of our company welcome friends both at home and abroad to come for visits and business on the basis of equality and mutual benefit. If you are interested in any of our items, please feel free to contact us for quotation and product details.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!