China Wholesale Hot sell in China for Servo Tapping Machine Suppliers - Spiral Flute Tap – MeiWha

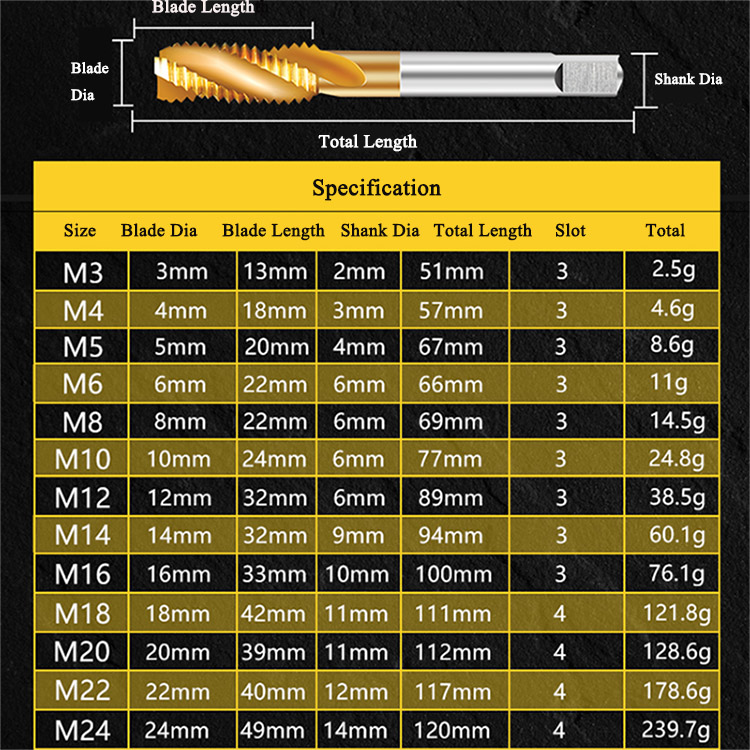

China Wholesale Hot sell in China for Servo Tapping Machine Suppliers - Spiral Flute Tap – MeiWha Detail:

Following are recommendations for the degree of spiral for various materials:

Spiral flute taps are more suitable for processing non-through hole threads (also called blind holes), and the chips are upward during processing discharge. Due to the helix angle, the actual cutting rake angle of the tap will increase as the helix angle increases.

• High spiral flutes 45° and higher – effective for very ductile materials like aluminum and copper. If used in other materials, they will usually cause the chips to nest because the spiral is too • fast and the chip area is too small for the chip to form correctly.

• Spiral flutes 38° – 42° – recommended for medium to high carbon steel or free machining stainless steel. They form a chip tight enough to easily evacuate. On larger taps, it allows for pitch relief to ease the cutting.

• Spiral flutes 25° – 35° – recommended for free machining, low or leaded steels, free machining bronze, or brasses. Spiral flute taps used in brass and tough bronzes normally do not perform well because the small broken chip will not flow up the spiral flute well.

• Spiral flutes 5° – 20° – For tougher materials such as some stainless, titanium or high nickel alloys, a slower spiral is recommended. This allows the chips to be slightly pulled upward but does not weaken the cutting edge as much as higher spirals will.

• Reverse cut spirals, such as RH cut/LH spiral, will push the chips forward and are usually 15° spiral. These work especially well in tubing applications.

Product detail pictures:

Related Product Guide:

Sticking for the basic principle of "Super Top quality, Satisfactory service" ,We've been striving to be an excellent business enterprise partner of you for China Wholesale Hot sell in China for Servo Tapping Machine Suppliers - Spiral Flute Tap – MeiWha , The product will supply to all over the world, such as: Bhutan, Iran, Houston, We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced products constantly to satisfactorily meet the needs of our clients all over the world.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!