Tapping Machine

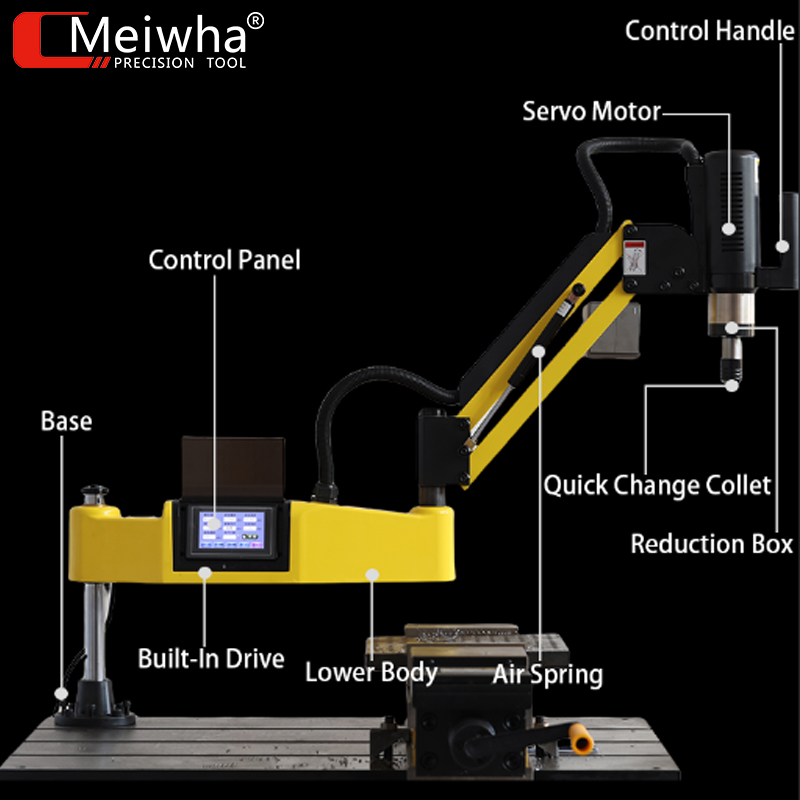

Meiwha Electric Tapping Machine, adopt the best advanced electric servo intelligent system. Used for steel, aluminum, wood plastic and other tapping. imported motor ,cast iron body, double cantilever ,double pneumatic spring, table support, automatic return, cast iron body is not easy to deformation intelligent servo system, man-machine interface, powerful function, manual, automatic, vibration tapping mode to meet a variety of processing needs, with torque overload protection chuck, protection tap will not break.

Tapping Machine Features:

1.High productivity, significant time savings compared to manual tapping

2.Higher accuracy compared to manual tapping, thread is guaranteed right angle (90 °)

3.Including swivel arm with large radius for easy positioning of the tap drill on the workpiece

4.Tiltable motor unit for tapping at any required angle between 0° and 90°

5.Highly economical due to low investment and maintenance costs

6.Includes quick change chuck for use of taps for through and blind holes

7.For tapping in steel, stainless steel, aluminum and non-ferrous metals

8.Quick-change chuck with integrated safety clutch prevents breakage of the tap drill

9.Optionally available magnetic base for direct use on large and heavy workpieces

With the above salient features of electric tapping machine, it is widely been used in industries in the process of tapping. The tapping machines in industries are used in creating taper holes whereas tapping refers to cutting of thread with the help of a tap. There are also different parts and range of tapping machine available that are been used according to the type of surface material that needs to be drilled. Our electric tapping machine is been manufactured using premium quality metals that assures trouble free performance and gives the best results that meets the desired need.

To know more about this and get an electric tapping machine in China contact us today & get high quality electric tapping machine in UAE as well.

| Cat.No | Tapping Range | Tapping Direction | Voltage/power | Output Reduction Ratio | Speed(rpm/min) | Working Radius | Weight(KG) |

| M3-12-C1K | M≤M12·P≤M12 | Vertical | 220V/600W | 1:16 | 0-312 | 1100mm | 27 |

| M3-12-C2K | M≤M12·P≤M12 | Vertical/horizontal | 220V/600W | 1:16 | 0-312 | 1100mm | 27 |

| M3-16-C1K | M≤M14·P≤M16 | Vertical | 220V/600W | 1:16 | 0-312 | 1100mm | 27 |

| M3-16-C2K | M≤M14·P≤M16 | Vertical/horizontal | 220V/600W | 1:16 | 0-312 | 1100mm | 27 |

| M3-20-C1K | M≤M20·P≤M20 | Vertical | 220v/1200w | 1:12 | 0-414 | 1200mm | 45 |

| M3-20-C2K | M≤M20·P≤M20 | Vertical/horizontal | 220v/1200w | 1:12 | 0-414 | 1200mm | 45 |

| M6-24-C1K | M≤M24·P≤M24 | Vertical | 220v/1200w | 1:25 | 0-200 | 1200mm | 45 |

| M6-24-C2K | M≤M24·P≤M24 | Vertical/horizontal | 220v/1200w | 1:25 | 0-200 | 1200mm | 45 |

| M6-30-C1K | M≤M24·P≤M30 | Vertical | 220v/1200w | 1:25 | 0-200 | 1200mm | 45 |

| M6-30-C2K | M≤M24·P≤M30 | Vertical/horizontal | 220v/1200w | 1:25 | 0-200 | 1200mm | 45 |

| M6-36-C1K | M≤M36·P≤M36 | Vertical | 220v/1200w | 1:40 | 0-125 | 1200mm | 45 |

| M6-36-C2K | M≤M36·P≤M36 | Vertical/horizontal | 220v/1200w | 1:40 | 0-125 | 1200mm | 45 |

| M3-12-C1X | M≤M10·P≤M12 | Vertical | 220V/1000W | 1:05 | 0-1200 | 1100MM | 27 |

| M3-12-C2X | M≤M10·P≤M12 | Vertical/horizontal | 220V/1000W | 1:05 | 0-1200 | 1100MM | 27 |

| M3-16-C1X | M≤M14·P≤M16 | Vertical | 220V/1000W | 1:16 | 0-375 | 1100MM | 27 |

| M3-16-C2X | M≤M14·P≤M16 | Vertical/horizontal | 220V/1000W | 1:16 | 0-375 | 1100MM | 27 |

| M3-20-C1X | M≤M16·P≤M20 | Vertical | 220V/1000W | 1:20 | 0-300 | 1100MM | 27 |

| M3-20-C2X | M≤M16·P≤M20 | Vertical/horizontal | 220V/1000W | 1:20 | 0-300 | 1100MM | 27 |

| M6-24-C1X | M≤M24·P≤M24 | Vertical | 220V/1800W | 1:25 | 0-240 | 1200MM | 47 |

| M6-24-C2X | M≤M24·P≤M24 | Vertical/horizontal | 220V/1800W | 1:25 | 0-240 | 1200MM | 47 |

| M6-30-C1X | M≤M24·P≤M30 | Vertical | 220V/1800W | 1:25 | 0-240 | 1200MM | 47 |

| M6-30-C2X | M≤M24·P≤M30 | Vertical/horizontal | 220V/1800W | 1:25 | 0-240 | 1200MM | 47 |

| M6-36-C1X | M≤M30·P≤M36 | Vertical | 220V/1800W | 1:35 | 0-171 | 1200MM | 47 |

| M6-36-C2X | M≤M30·P≤M36 | Vertical/horizontal | 220V/1800W | 1:35 | 0-171 | 1200MM | 47 |

| Accessories: 1xTapping Machine,1xCollets siet,1xToolkit,1xPower Cord,1xStand Column | |||||||

Meiwha Tapping Machine Series

Meiwha Electric Tapping Machine

Steel Tapping, Aluminum Tapping, Plastic Tapping, Wood Tapping

Intelligent Control Touch Screen

Can detect torque values in real time, Dual - language interface setup, real - time torque display, and a more intelligent operating system.

High Vertical Angle

Professional tapping fast accurate sready, significantly improved efficiency ensuring the perpendicularity of the screw holes and meeting industrial requirements, extend taps' service life.

Pure Copper Server Motor

Sufficient motivation to carry out efficient tapping, pure copper motors powerful, stable and durable performance, reducing the risk of overheating.

Double Copper Sleeve and Double Berings

Reduce friction and loger lifespan, high - strength and wear - resistant copper sleeves are used at all the joints of the machine. Reduce the friction when moving the machine joints and increase the service life.