Shrink Fit Tool Holder

Meiwha’s Shrink Fit Tool Holder with standard and long reach gage length and coolant thru type in variety of popular taper spindle including dual contact CAT40, CAT50, BT30, BT40, HSK63A, and straight shank.

Meiwha’s shrink fit tool holders blend precision and efficiency seamlessly. Engineered for versatility in mold making and multi-axis machinery applications, their slim design caters to low clearance and tight work envelopes, striking an ideal balance between the gripping strength of milling and collet chucks. This ensures a reliable solution across a broad spectrum of machining needs.

The straightforward design minimizes accessories while guaranteeing a solid grip on your tools. Despite the upfront investment required for the induction heating process, our shrink-fit tool holders assure long-term and efficient performance.

Enhance your machining experience with Meiwha shrink fit tool holders, Offering a perfect blend of affordability, precision, and efficiency.

Features & Benefits

Slim Design for Tight Spaces: Engineered with a small nose diameter, perfect for low clearance and tight work envelopes.

Optimal Gripping Strength: Boasts high clamping force, providing a reliable and powerful grip on tools for various machining needs.

Symmetrical Precision: Features a symmetrical design, ensuring balance and precision in every application.

| Cat.NO | Size | ||||||

| D | d1 | d2 | L | A | B | ||

| BT/BBT30 | SF04-80 | 4 | 10 | 15 | 80 | 128.4 | 36 |

| SF06-80 | 6 | 19 | 25 | 80 | 128.4 | 36 | |

| SF08-80 | 8 | 21 | 27 | 80 | 128.4 | 36 | |

| SF10-80 | 10 | 23 | 32 | 80 | 128.4 | 40 | |

| SF12-80 | 12 | 25 | 33 | 80 | 128.4 | 40 | |

| SF14-80 | 14 | 27 | 34 | 80 | 128.4 | 50 | |

| SF16-80 | 16 | 29 | 36 | 80 | 128.4 | 50 | |

| SF18-80 | 18 | 31 | 40 | 80 | 128.4 | 50 | |

| SF20-90 | 20 | 33 | 40 | 90 | 138.4 | 50 | |

| SF06-120 | 6 | 19 | 25 | 120 | 168.4 | 36 | |

| SF08-120 | 8 | 21 | 27 | 120 | 168.4 | 36 | |

| SF10-120 | 10 | 23 | 32 | 120 | 168.4 | 50 | |

| SF12-120 | 12 | 25 | 33 | 120 | 168.4 | 50 | |

| SF14-120 | 14 | 27 | 34 | 120 | 168.4 | 50 | |

| SF16-120 | 16 | 29 | 36 | 120 | 168.4 | 50 | |

| SF18-120 | 18 | 31 | 40 | 120 | 168.4 | 50 | |

| SF20-120 | 20 | 33 | 40 | 120 | 168.4 | 50 | |

| BT/BBT40 | SF04-90 | 4 | 10 | 15 | 90 | 155.4 | 36 |

| SF06-90 | 6 | 19 | 25 | 90 | 155.4 | 36 | |

| SF08-90 | 8 | 21 | 27 | 90 | 155.4 | 36 | |

| SF10-90 | 10 | 23 | 32 | 90 | 155.4 | 40 | |

| SF12-90 | 12 | 25 | 33 | 90 | 155.4 | 40 | |

| SF14-90 | 14 | 27 | 34 | 90 | 155.4 | 50 | |

| SF16-90 | 16 | 29 | 36 | 90 | 155.4 | 50 | |

| SF18-90 | 18 | 31 | 40 | 90 | 155.4 | 50 | |

| SF20-90 | 20 | 33 | 40 | 90 | 155.4 | 50 | |

| SF25-90 | 25 | 38 | 47 | 90 | 155.4 | 55 | |

| SF04-120 | 4 | 10 | 15 | 120 | 185.4 | 36 | |

| SF06-120 | 6 | 19 | 25 | 120 | 185.4 | 36 | |

| SF08-120 | 8 | 21 | 27 | 120 | 185.4 | 36 | |

| SF10-120 | 10 | 23 | 32 | 120 | 185.4 | 40 | |

| SF12-120 | 12 | 25 | 33 | 120 | 185.4 | 40 | |

| SF14-120 | 14 | 27 | 34 | 120 | 185.4 | 50 | |

| SF16-120 | 16 | 29 | 36 | 120 | 185.4 | 50 | |

| SF18-120 | 18 | 31 | 40 | 120 | 185.4 | 50 | |

| SF20-120 | 20 | 33 | 40 | 120 | 185.4 | 50 | |

| SF25-120 | 25 | 38 | 47 | 120 | 185.4 | 55 | |

| SF04-150 | 4 | 10 | 15 | 150 | 215.4 | 36 | |

| SF06-150 | 6 | 19 | 25 | 150 | 215.4 | 36 | |

| SF08-150 | 8 | 21 | 27 | 150 | 215.4 | 36 | |

| SF10-150 | 10 | 23 | 32 | 150 | 215.4 | 40 | |

| SF12-150 | 12 | 25 | 33 | 150 | 215.4 | 40 | |

| SF14-150 | 14 | 27 | 34 | 150 | 215.4 | 50 | |

| SF16-150 | 16 | 29 | 36 | 150 | 215.4 | 50 | |

| SF18-150 | 18 | 31 | 40 | 150 | 215.4 | 50 | |

| SF20-150 | 20 | 33 | 40 | 150 | 215.4 | 50 | |

| SF25-150 | 25 | 38 | 47 | 150 | 215.4 | 55 | |

| BT/BBT50 | SF06-100 | 6 | 19 | 25 | 100 | 201.8 | 36 |

| SF08-100 | 8 | 21 | 27 | 100 | 201.8 | 36 | |

| SF10-100 | 10 | 23 | 32 | 100 | 201.8 | 40 | |

| SF12-100 | 12 | 25 | 33 | 100 | 201.8 | 40 | |

| SF14-100 | 14 | 27 | 34 | 100 | 201.8 | 50 | |

| SF16-100 | 16 | 29 | 36 | 100 | 201.8 | 50 | |

| SF18-100 | 18 | 31 | 40 | 100 | 201.8 | 50 | |

| SF20-100 | 20 | 33 | 40 | 100 | 201.8 | 50 | |

| SF25-100 | 25 | 38 | 47 | 100 | 201.8 | 55 | |

| SF06-150 | 6 | 19 | 25 | 150 | 251.8 | 36 | |

| SF08-150 | 8 | 21 | 27 | 150 | 251.8 | 36 | |

| SF10-150 | 10 | 23 | 32 | 150 | 251.8 | 40 | |

| SF12-150 | 12 | 25 | 33 | 150 | 251.8 | 40 | |

| SF14-150 | 14 | 27 | 34 | 150 | 251.8 | 50 | |

| SF16-150 | 16 | 29 | 36 | 150 | 251.8 | 50 | |

| SF18-150 | 18 | 31 | 40 | 150 | 251.8 | 50 | |

| SF20-150 | 20 | 33 | 40 | 150 | 251.8 | 50 | |

| SF25-150 | 25 | 38 | 47 | 150 | 251.8 | 55 | |

| Cat.No | Size | Gripping range |

||||||||

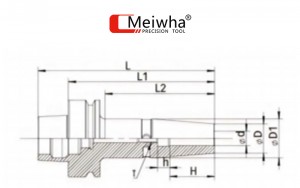

| L | L1 | L2 | D | D1 | H | h | T | |||

| HSK50A | -SF03-60 | 85 | 60 | 30 | 10 | 16 | 9 | / | / | 3 |

| -SF04-60 | 85 | 60 | 30 | 10 | 16 | 12 | / | / | 4 | |

| -SF05-60 | 85 | 60 | 30 | 10 | 16 | 15 | / | / | 5 | |

| -SF06-80 | 105 | 80 | 51 | 21 | 27 | 26 | 10 | M5 | 6 | |

| -SF08-80 | 105 | 80 | 51 | 21 | 27 | 26 | 10 | M6 | 8 | |

| -SF10-85 | 110 | 85 | 56 | 24 | 32 | 32 | 10 | M6 | 10 | |

| -SF12-90 | 115 | 90 | 61 | 24 | 32 | 37 | 10 | M6 | 12 | |

| -SF14-90 | 115 | 90 | 61 | 27 | 34 | 37 | 10 | M6 | 14 | |

| -SF16-95 | 120 | 95 | 66 | 27 | 34 | 40 | 10 | M8 | 16 | |

| HSK63A | -SF03-80 | 112 | 80 | 48 | 10 | 16 | 9 | / | / | 3 |

| -SF03-130 | 162 | 130 | 98 | 10 | 16 | 9 | / | / | 3 | |

| -SF04-80 | 112 | 80 | 48 | 10 | 16 | 12 | / | / | 4 | |

| -SF04-130 | 162 | 130 | 98 | 10 | 16 | 12 | / | / | 4 | |

| -SF05-80 | 112 | 80 | 48 | 10 | 16 | 15 | / | / | 3 | |

| -SF05-130 | 162 | 130 | 98 | 10 | 16 | 15 | / | / | 3 | |

| -SF06-80 | 112 | 80 | 51 | 21 | 27 | 26 | 10 | M5 | 6 | |

| -SF06-130 | 162 | 130 | 101 | 21 | 27 | 26 | 10 | M5 | 6 | |

| -SF06-160 | 192 | 160 | 131 | 21 | 27 | 26 | 10 | M5 | 6 | |

| -SF06-200 | 232 | 200 | 171 | 21 | 27 | 26 | 10 | M5 | 6 | |

| -SF08-80 | 112 | 80 | 51 | 21 | 27 | 26 | 10 | M6 | 8 | |

| -SF08-130 | 162 | 130 | 101 | 21 | 27 | 26 | 10 | M6 | 8 | |

| -SF08-160 | 192 | 160 | 131 | 21 | 27 | 26 | 10 | M6 | 8 | |

| -SF08-200 | 232 | 200 | 171 | 21 | 27 | 26 | 10 | M6 | 8 | |

| -SF10-85 | 117 | 85 | 56 | 24 | 32 | 32 | 10 | M6 | 10 | |

| -SF10-130 | 162 | 130 | 101 | 24 | 32 | 32 | 10 | M6 | 10 | |

| -SF10-160 | 192 | 160 | 131 | 24 | 32 | 32 | 10 | M6 | 10 | |

| -SF10-200 | 232 | 200 | 171 | 24 | 32 | 32 | 10 | M6 | 10 | |

| -SF12-90 | 122 | 90 | 56 | 24 | 32 | 37 | 10 | M6 | 12 | |

| -SF12-130 | 162 | 130 | 101 | 24 | 32 | 37 | 10 | M6 | 12 | |

| -SF12-160 | 192 | 160 | 131 | 24 | 32 | 37 | 10 | M6 | 12 | |

| -SF12-200 | 232 | 200 | 171 | 24 | 32 | 37 | 10 | M6 | 12 | |

| -SF14-90 | 122 | 90 | 56 | 27 | 34 | 37 | 10 | M6 | 14 | |

| -SF14-130 | 162 | 130 | 101 | 27 | 34 | 37 | 10 | M6 | 14 | |

| -SF14-160 | 192 | 160 | 131 | 27 | 34 | 37 | 10 | M6 | 14 | |

| -SF14-200 | 232 | 200 | 171 | 27 | 34 | 37 | 10 | M6 | 14 | |

| -SF16-95 | 127 | 95 | 66 | 27 | 34 | 40 | 10 | M8 | 16 | |

| -SF16-130 | 162 | 130 | 101 | 27 | 34 | 40 | 10 | M8 | 16 | |

| HSK63A | -SF16-160 | 192 | 160 | 131 | 27 | 34 | 40 | 10 | M8 | 16 |

| -SF16-200 | 232 | 200 | 171 | 27 | 34 | 40 | 10 | M8 | 16 | |

| -SF18-95 | 127 | 95 | 69 | 33 | 42 | 40 | 10 | M8 | 18 | |

| -SF18-130 | 162 | 130 | 101 | 33 | 42 | 40 | 10 | M8 | 18 | |

| -SF18-160 | 192 | 160 | 131 | 33 | 42 | 40 | 10 | M8 | 18 | |

| -SF18-200 | 232 | 200 | 171 | 33 | 42 | 40 | 10 | M8 | 18 | |

| -SF20-100 | 132 | 100 | 71 | 33 | 42 | 42 | 10 | M8 | 20 | |

| -SF20-130 | 162 | 130 | 101 | 33 | 42 | 40 | 10 | M8 | 20 | |

| -SF20-160 | 192 | 160 | 131 | 33 | 42 | 40 | 10 | M8 | 20 | |

| -SF20-200 | 232 | 200 | 171 | 33 | 42 | 40 | 10 | M8 | 20 | |

| -SF25-115 | 147 | 115 | 89 | 44 | 53 | 48 | 10 | M16 | 25 | |

| -SF25-130 | 162 | 130 | 104 | 44 | 53 | 48 | 10 | M16 | 25 | |

| -SF25-160 | 192 | 160 | 134 | 44 | 53 | 48 | 10 | M16 | 25 | |

| -SF25-200 | 232 | 200 | 174 | 44 | 53 | 48 | 10 | M16 | 25 | |

| -SF32-120 | 152 | 120 | 94 | 44 | 53 | 48 | 10 | M16 | 32 | |

| -SF32-160 | 192 | 160 | 134 | 44 | 53 | 48 | 10 | M16 | 32 | |

| -SF32-200 | 232 | 200 | 174 | 44 | 53 | 48 | 10 | M16 | 32 | |

| HSK100A | -SF06-85 | 135 | 85 | 45 | 21 | 27 | 26 | 10 | M5 | 6 |

| -SF06-130 | 180 | 130 | 87 | 21 | 27 | 26 | 10 | M5 | 6 | |

| -SF06-160 | 210 | 160 | 117 | 21 | 27 | 26 | 10 | M5 | 6 | |

| -SF06-200 | 250 | 200 | 157 | 21 | 27 | 26 | 10 | M5 | 6 | |

| -SF08-85 | 135 | 85 | 45 | 21 | 27 | 26 | 10 | M6 | B | |

| -SF08-130 | 180 | 130 | 87 | 21 | 27 | 26 | 10 | M6 | 8 | |

| -SF08-160 | 210 | 160 | 117 | 21 | 27 | 26 | 10 | M6 | 8 | |

| -SF08-200 | 250 | 200 | 157 | 21 | 27 | 26 | 10 | M6 | 8 | |

| -SF10-90 | 140 | 90 | 51 | 24 | 32 | 32 | 10 | M6 | 10 | |

| -SF10-130 | 180 | 130 | 91 | 24 | 32 | 32 | 10 | M6 | 10 | |

| -SF10-160 | 210 | 160 | 121 | 24 | 32 | 32 | 10 | M6 | 10 | |

| -SF10-200 | 250 | 200 | 161 | 24 | 32 | 32 | 10 | M6 | 10 | |

| -SF12-95 | 145 | 95 | 56 | 24 | 32 | 37 | 10 | M6 | 12 | |

| -SF12-130 | 180 | 130 | 96 | 24 | 32 | 37 | 10 | M6 | 12 | |

| -SF12-160 | 210 | 160 | 126 | 24 | 32 | 37 | 10 | M6 | 12 | |

| -SF12-200 | 250 | 200 | 161 | 24 | 32 | 37 | 10 | M6 | 12 | |

| -SF14-95 | 145 | 95 | 56 | 27 | 34 | 37 | 10 | M6 | 14 | |

| -SF14-130 | 180 | 130 | 96 | 27 | 34 | 37 | 10 | M6 | 14 | |

| -SF14-160 | 210 | 160 | 126 | 27 | 34 | 37 | 10 | M6 | 14 | |

| -SF14-200 | 250 | 200 | 166 | 27 | 34 | 37 | 10 | M6 | 14 | |

| -SF16-100 | 150 | 100 | 66 | 27 | 34 | 40 | 10 | M8 | 16 | |

| -SF16-130 | 180 | 130 | 96 | 27 | 34 | 40 | 10 | M8 | 16 | |

| -SF16-160 | 210 | 160 | 126 | 27 | 34 | 40 | 10 | M8 | 16 | |

| -SF16-200 | 250 | 200 | 166 | 27 | 34 | 40 | 10 | M8 | 16 | |

| HSK100A | -SF18-100 | 150 | 100 | 66 | 33 | 42 | 40 | 10 | M8 | 18 |

| -SF18-130 | 180 | 130 | 96 | 33 | 42 | 40 | 10 | M8 | 18 | |

| -SF18-160 | 210 | 160 | 126 | 33 | 42 | 40 | 10 | M8 | 18 | |

| -SF18-200 | 250 | 200 | 166 | 33 | 42 | 40 | 10 | M8 | 18 | |

| -SF20-105 | 155 | 105 | 71 | 33 | 42 | 42 | 10 | M8 | 20 | |

| -SF20-130 | 180 | 130 | 96 | 33 | 42 | 42 | 10 | M8 | 20 | |

| -SF20-160 | 210 | 160 | 126 | 33 | 42 | 42 | 10 | M8 | 20 | |

| -SF20-200 | 250 | 200 | 166 | 33 | 42 | 42 | 10 | M8 | 20 | |

| -SF25-115 | 165 | 115 | 81 | 44 | 53 | 48 | 10 | M16 | 25 | |

| -SF25-130 | 180 | 130 | 96 | 44 | 53 | 48 | 10 | M16 | 25 | |

| -SF25-160 | 210 | 160 | 126 | 44 | 53 | 48 | 10 | M16 | 25 | |

| -SF25-200 | 250 | 200 | 166 | 44 | 53 | 48 | 10 | M16 | 25 | |

| -SF32-130 | 180 | 130 | 96 | 44 | 53 | 48 | 10 | M16 | 32 | |

| -SF32-160 | 210 | 160 | 126 | 44 | 53 | 48 | 10 | M16 | 32 | |

| -SF32-200 | 250 | 200 | 166 | 44 | 53 | 48 | 10 | M16 | 32 | |

Meiwha Shrink Fit Holder

High Precision Choice Durable & Wear - Resistant

Complete specifications and sufficient stock

BT/BTFL Series: Compliant with JIS standards, covering common specifications such as BT30, BT40, BT50, etc. It is a classic choice for vertical machining centers.

CAT/CAT-V series: Compliant with ANSI standards (such as CAT40, CAT50), similar in appearance to the BT series but with different snap pins. Widely used in the North American market.

HSK Series: As a benchmark in the field of high-speed machining, we offer a complete HSK solution, including:

HSK-A and HSK-C types: Suitable for general high-speed machining centers.

HSK-E and HSK-F models: Specifically designed for ultra-high-speed machining and excellent dynamic balance performance.

Other mainstream interfaces: We also offer tool handles with interfaces such as DIN 69871(SK) and MAS 403(NT), fully meeting your diverse needs.

long service life

Under correct operation conditions, even if the same tool handle is subjected to more than 2000 thermal loading and unloading cycles, its accuracy is unlikely to deteriorate, ensuring stability and reliability. (It is recommended to be equipped with the Meiwha Shrink Fit Machine)

High flexibility, few interferences

The front end of the knife handle can be designed to be extremely small and lightweight (for example, the wall thickness of the ultra-thin front part can reach 1.5mm).

Shrink fit tool holder reduces the possibility of interference between the processing and the workpiece during the manufacturing process, and is highly suitable for cavity and deep cavity processing.

The one-piece shrink fit tool holder can set the protruding length of the tool to the minimum, thus enabling high rigidity and powerful stability in cutting. The vibration is nearly zero, resulting in high-quality processing, and it can also extend the service life of the tool.