Precision Vise

-

Meiwha CNC Plane Hydraulic Vise

Made of ductile iron casting, through radial quenching hardening. with better rigidity. Mainly used for grinding machines, milling machines. CNC machining centers, etc.

The jaws are detachable and can be quickly replaced, effectively reducing maintenance costs.

-

Meiwha CNC Pneumatic Hydraulic Vise

The pneumatic hydraulic vise is an automated vise that utilizes air pressure as the power source. It converts the air pressure into hydraulic pressure through a hydraulic multiplier, thereby generating a huge clamping force. The pneumatic hydraulic vise combines the fast response of pneumatic technology and the tremendous force of hydraulic technology.

-

Meiwha MC Double Clamping Precision Vise

The MC Double Clamping Precision Vise is a highly efficient fixture that is widely popular in the field of mechanical processing, especially on CNC milling machines and machining centers. The MC Double Clamping Precision Vise is designed to achieve rapid positioning, batch production, and extremely high rigidity.

-

Meiwha Double Station Vise

Dual Station Vise, doubling the processing efficiency. We provide high-quality clamping solutions specifically for modern CNC machines.

-

Meiwha Punch Former

Punch former is the fixture to grind the point of standard punches and E.D.M. electrodes for precise and fast operation. Besides the round, radius and multiangle punches, any special forms can be ground precisely.

Punch Former is the great dressing instrument. precisely forming the ginder whell can be done by assembling an ARM with the main body. Any combination of tangents or radil form of the grinding wheel may be dressed accurately by easy operation.

-

Self Centering Vise

Updated self-centering CNC machine vise with increased clamping force.

Self-centering technology for easy workpiece positioning.

5-inch jaw width and quick-change design for versatility.

Precision construction from heat-treated steel ensures accuracy. -

3-Jaw High Precision Hydraulic Chuck

Product Model: 3-Jaw Chuck

Product Material: Settle

Product Specification: 5/6/7/8/10/15

Rotation Precision: 0.02mm

Maximum Pressure: 29

Maximum Tension: 5500

Maximum Static Clamping:14300

Maximum Speed of Revolution: 8000

-

CNC Machining Center Multi-Station Precision Vise Mechanical Vice

Application:Punching Machine, Grinding Machine, Slotting Machine, Milling Machine, Drilling Machine, Boring Machine, Mounted on The Table or The Pallet.

ChuckApplication:Punching Machine, Grinding Machine, Slotting Machine, Milling Machine, Drilling Machine, Boring Machine, Mounted on The Table or The Pallet Chuck.

-

Meiwha Self-Centering Vise

Bearing material: Martensitic stainless steel

Precision Grade: 0.01mm

Locking Method: Spanner

Applicable Temperature:30-120

Coating type: Titanium plating coating

Bearing type: Bidirectional screw rod

Steel hardness:HRC58-62

Packaging method: Oil-coated foam carton

-

MC Precision Vise

Wide range of high-quality vises designed to provide the utmost stability and accuracy for your delicate projects.

-

High Precision Vise Model 108

Product Material: Titanium Manganese Allou Steel

Clamp Opening Width:4/5/6/7/8 inches

Product Precision: ≤0.005mm

-

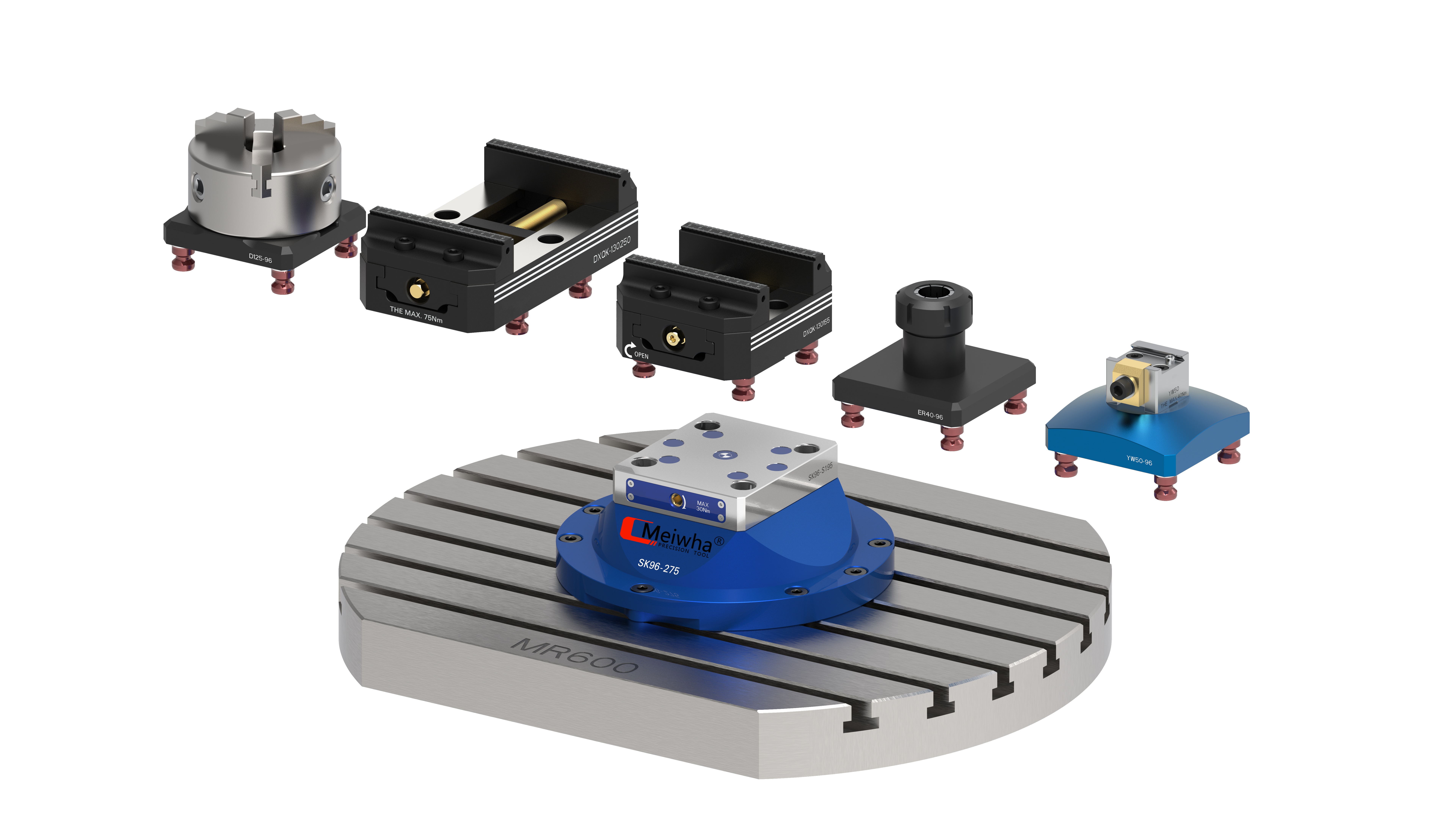

5 AXIS MACHINE CLAMP FIXTURE SET

Steel Workpiece Zero Point CNC Machine 0.005mm Repeat Position zero point clamping quick-change pallet system The four-hole zero-point locator is a positioning tool that can quickly exchange fixtures and fixed fixtures, The standard installation method enables tools such as vices, pallets, chucks, etc, to be quickly and repeatedly changed between various cnc machine tools. No need to disassemble and calibrate time. Manual Flexible Adjustable Self Centering Vise For Cnc Milling Machine...