Products

-

CNC Machine Side Milling Head Universal Angle Head Tool Holder BT & CAT & SK Standards

3500-4000 rpm Maximum Speed; 45 Nm Maximum Torque; 4 kW Maximum Power.

1:1 Input to Output Gear Ratio

0°-360° Radial Adjustment

CAT /BT/BBT/HSK Taper Shank; For ER Collets

Includes: Angle Head, Collet Wrench, Stop Block, Allen Key

-

Face Milling Cutter Head High Feed High Performance Milling Cutter

Face Milling Cutters are cutting tools used in milling machines to perform various milling operations.

It consists of a cutting head with multiple inserts that can remove material from a workpiece.

The design of the cutter allows for high-speed machining and efficient material removal.

-

Automatic/Manual Tool Holder Loader

Automatic/Manual Tool Holder Loader can free you from time and labour consuming hand operations, no more extra tools be needed with no safety risks. Saving space from large size tool seats. Avoiding unstable output torque and craft, damaged chucks, in order to reduce the cost. For large variety and quantity of tool holders, lower the storage difficulty.

-

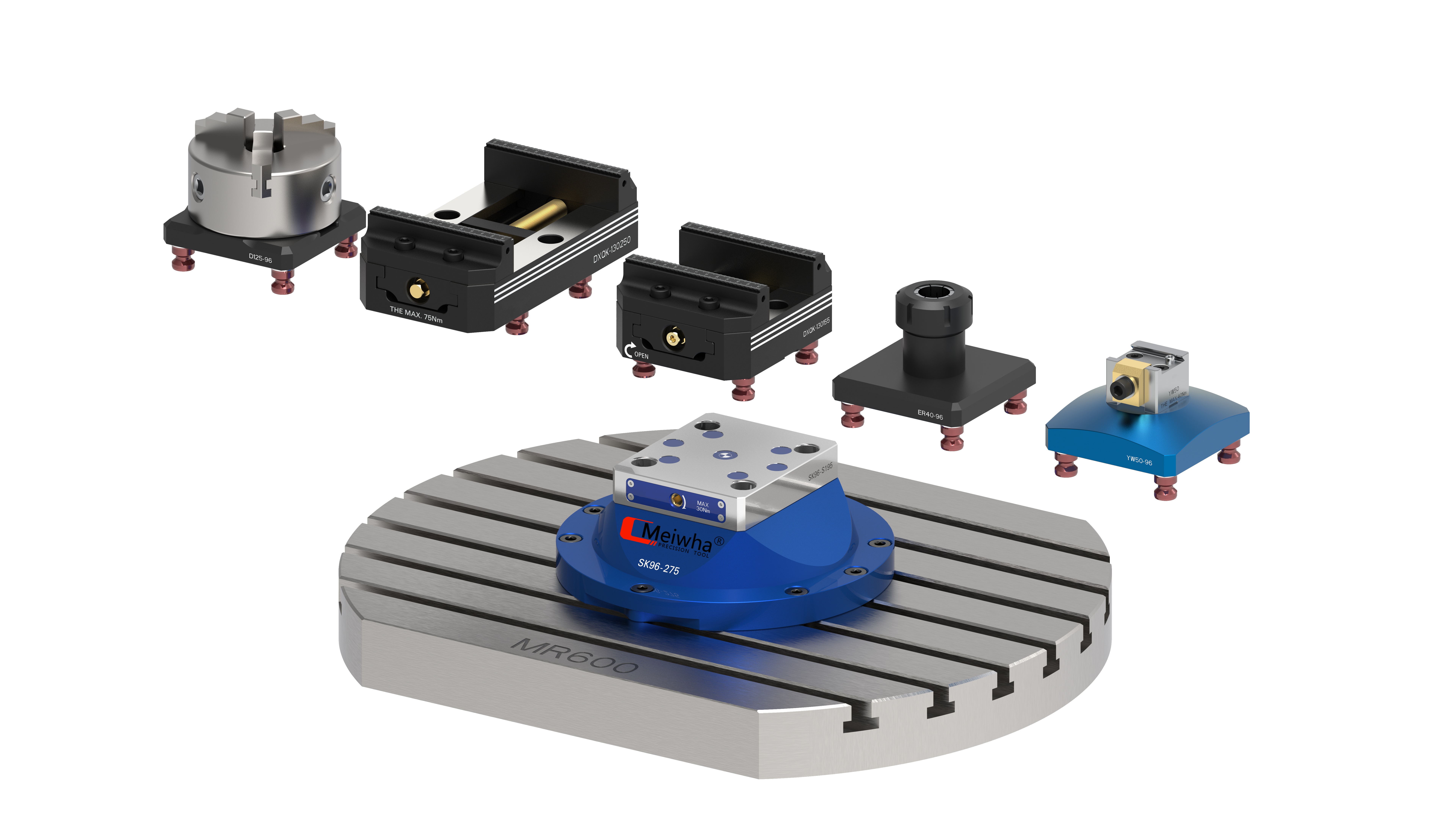

5 AXIS MACHINE CLAMP FIXTURE SET

Steel Workpiece Zero Point CNC Machine 0.005mm Repeat Position zero point clamping quick-change pallet system The four-hole zero-point locator is a positioning tool that can quickly exchange fixtures and fixed fixtures, The standard installation method enables tools such as vices, pallets, chucks, etc, to be quickly and repeatedly changed between various cnc machine tools. No need to disassemble and calibrate time. Manual Flexible Adjustable Self Centering Vise For Cnc Milling Machine... -

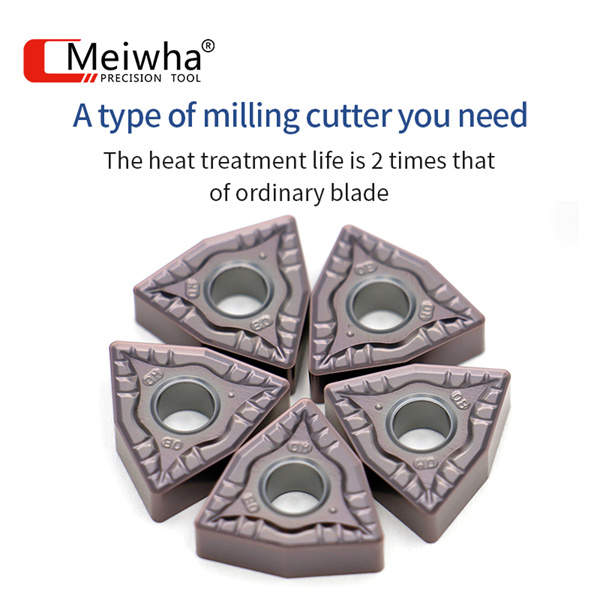

High End CNC Inserts

This High End CNC blade made of high quality tungsten steel with high wear resistance, low expansion efficient, and good corrosion resistance.

-

Heavy-duty Flat Bottom Milling Cutter CNC Milling For Titanium Alloy

·Product Material: Tungsten Carbide has the advantages of high hardness, wear resistance, toughness and corrosion resistance. It also has stronger heat resistance than HSS, so it can maintain hardness even at high temperature. Tungsten steel is mainly composed of tungsten carbide and cobalt, accounting for 99% of all components. Tungsten steel is also called cemented carbide and is considered to be the teeth of modern industry.

-

Meiwha Combined Precision Vise

Made of high-quality alloy steel 20CrMnTi,carburizing treatment, the hardness of working surface reaches HRC58-62. Parallelism 0.005mm/100mm, and squareness 0.005mm. It have interchangeable base, fixed /movable vice jaw is quickly to clamp and easy to operate. Used for precision measurement and inspection, precision grinding. EDM and wire-cutting machine. Guarantee high accuracy in any position. Precision combination vise are not ordinary type it is a new research High Precision Tool Vice.

-

Meiwha Vacuum Chuck MW-06A for CNC Process

Grid Size: 8*8mm

Workpiece Size: 120*120mm or more

Vacuum Range: -80KP – 99KP

Application Scope: Suitable for adsorbing workpieces of various materials (stainless steel, aluminum plate, copper plate, PC board, plastic, glass plate, etc.)

-

Meiwha Precision Vise

FCD 60 high quality ductile cast iron -body material-reduce the cutting vibration.

Angle-fixed design: for vertical & horizontal cutting &processing machine.

Everlasting clamping power.

Heavy cutting.

Hardness> HRC 45°: vise sliding bed.

High durability & high precision. Tolerance:0.01/100mm

Lift proof: press down design.

Bending resistance: rigid & strong

Dust proof: concealed spindle.

Fast &easy operation.

-

Drill Sharpener

MeiWha drill grinders sharpen drills accurately and quickly. Currently, MeiWha offers two drill grinding machines.

-

Meiwha MW-800R Slide Chamfering

Model: MW-800R

Voltage: 220V/380V

Rate of work: 0.75KW

Motor speed: 11000r/min

Guide rail travel distance: 230mm

Chamfer Angle: 0-5mm

Special high-precision product straight-edge chamfering. Utilizing the sliding track, it does damage the surface of the workpiece.

-

Meiwha MW-900 Grinding Wheel Chamfer

Model: MW-900

Voltage: 220V/380V

Rate of work: 1.1KW

Motor speed: 11000r/min

Straight line chamfer range: 0-5mm

Curved chamfer range: 0-3mm

Chamfer Angle: 45°

Dimensions: 510*445*510

It is particularly suitable for batch processing. The chamfering of the parts has a high degree of smoothness and no burrs.